What’s pad printing?

Pad printing technology also called tampography or tampo printing, is an indirect offset (gravure) printing process where a silicone pad takes the printing artwork from a pad printing plate (also called cliché) and transfers it to the work piece. Thanks to pad printing, it is now possible to print all kind of difficult shaped products such as curved (convex), hollow (concave), cylindrical, spherical, compound angles, textures, etc. which were not available with traditional printing processes.

Then,what’s the necessary printing supplies for pad printing?

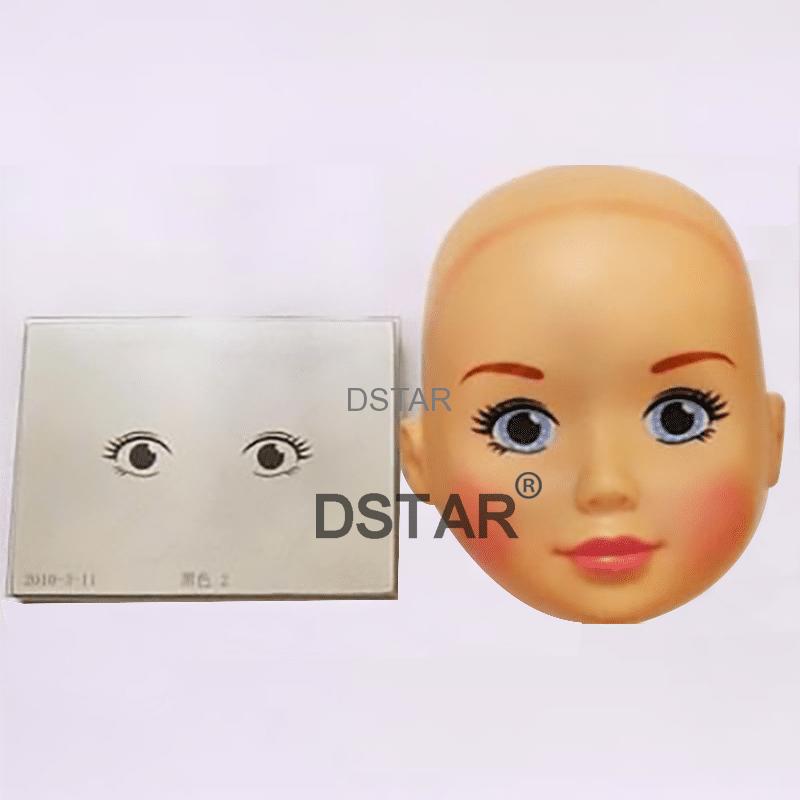

- Pad printing plate (cliché)

- Silicone pad

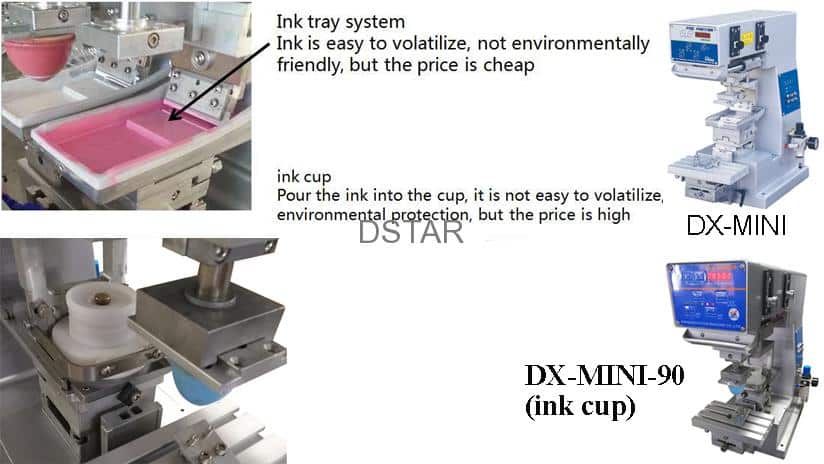

- Ink cup or ink blade (there are open ink well and sealed ink cup system for pad printing)

- Pad printing ink and ink thinner

- Fixture(also named jig) to hold work piece during printing

pad printing ink

Pad printing plate

Silicone pad

Ink blade

Ink cup

Pad printing consumables

The pad printer have two different ink scraping system:sealed ink cup and open ink well

Open ink well systems, the older method of pad printing, used an ink trough for the ink supply, which was located behind the printing plate. A flood bar pushed a pool of ink over the plate, and a doctor blade removes the ink from the plate surface, leaving ink on the etched artwork area ready for the pad to pick up.

Sealed ink cup systems employ a sealed container which acts as the ink supply, flood bar and doctor blade all at the same time. A ceramic ring or tungsten ring with a highly polished working edge provides the seal against the printing plate.

open ink well scraping

sealed ink cup system

Future of pad printing

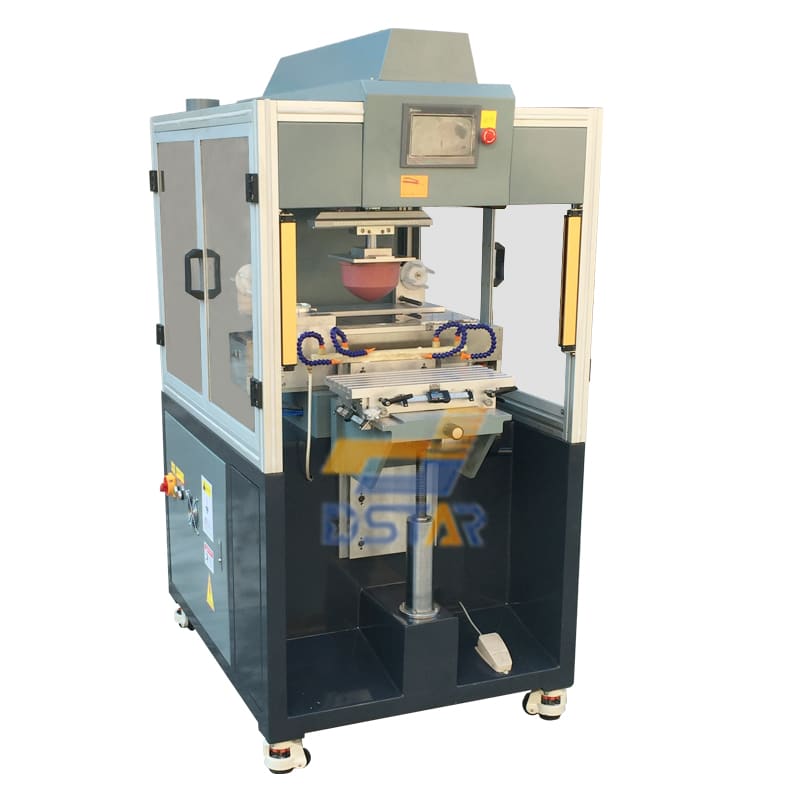

Pad printing is an irreplaceable printing technology. With the continuous innovation of technology, pad printing machines will be more intelligent and automated.

With the continuous increase of labor costs and the high requirements of users for productivity efficiency, the future trend of pad printing machines will be automation. In this way, automatic feeding, automatic printing, automatic ink drying and automatic unloading can be realized. And it can be customized according to different product requirements. , Increase the automatic printing quality detection function

Development

At present, DSTAR has developed and produced a variety of automatic pad printing machines and successfully applied in different industries. For example, automatic toy pad printing machine, automatic memory card pad printing machine, automatic size clip pad printing machine, automatic pen clip printing machine Machines, etc. DSTAR can add customized functions according to customer needs, such as CCD visual inspection, automatic pad printing rubber head cleaning, automatic product rotation and flip printing, etc.

phone glass pad printing

LEGO toy printing machine

automatic 2 color pad printing machine

DSTAR machine

DSTAR machine

WeChat

Scan the QR Code with wechat