tagless pad printing machine for T-shirt and underwear

The application of tagless pad printing machine in printing wash care labels on T-shirts and underwear offers several advantages, particularly in terms of precision, efficiency, and versatility. Here’s how pad printing is used in these applications:

- Precise Printing on Soft Fabrics:

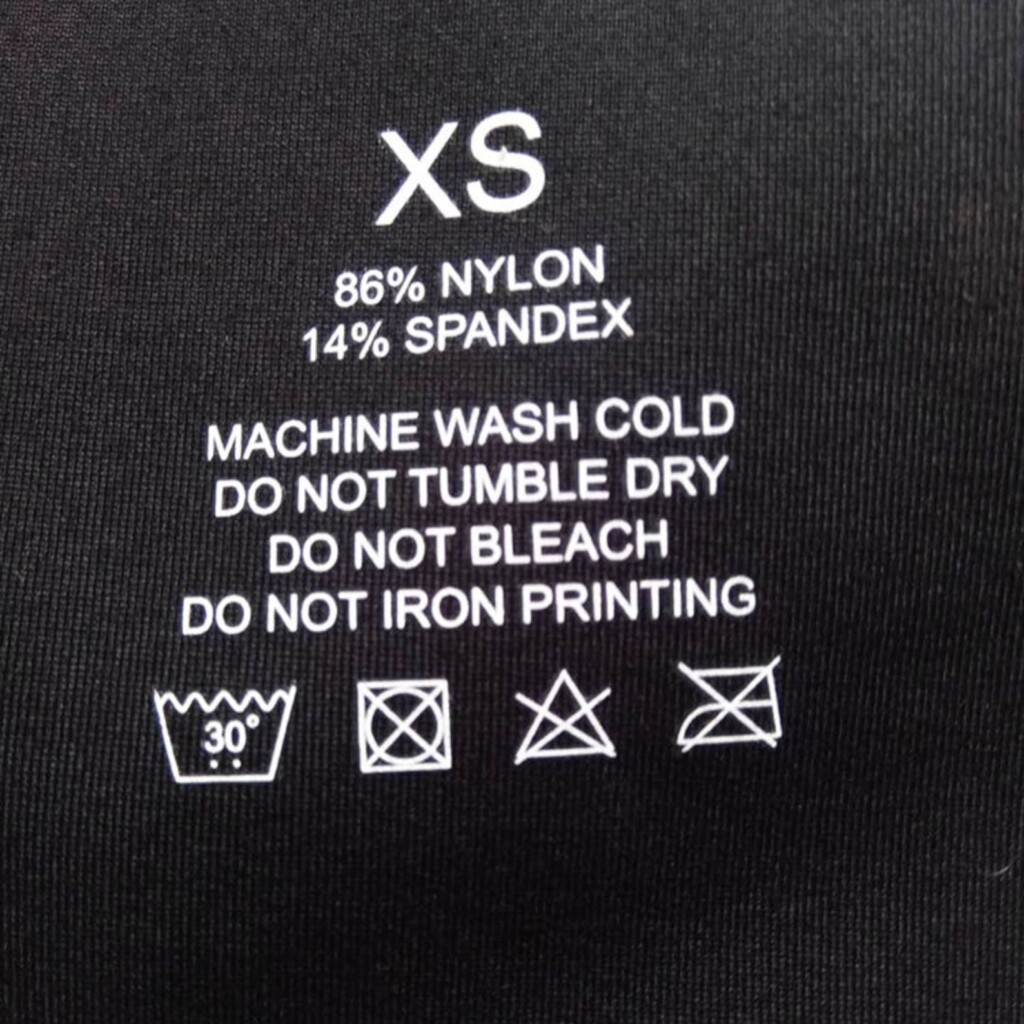

Pad printing machines are ideal for printing on soft, flexible fabrics like those used in T-shirts and underwear. The machine uses a silicone pad to transfer ink onto the fabric, ensuring that even fine details, such as small text and intricate logos, are printed clearly and accurately. - Adaptability to Curved Surfaces:

Unlike traditional printing methods, pad printing can easily handle printing on curved or irregular surfaces. This is particularly useful for T-shirt and underwear labels, which may be sewn into the garment or positioned in areas where other printing methods might struggle to maintain quality. - Durability of Prints:

Pad printing inks are designed to be durable, ensuring that the printed wash care labels remain intact even after multiple washes. The prints are resistant to fading, cracking, or peeling, making them a reliable option for labels that will be exposed to frequent laundering. - High Production Speed:

Pad printing machines are highly efficient, enabling high-speed printing for large batches of garments. This is particularly advantageous for mass production of T-shirts and underwear, where fast turnaround times are essential. - Comfort and Softness:

Since pad printing applies ink directly onto the fabric without adding extra layers of material, the printed labels remain soft and comfortable. This is crucial for garments like T-shirts and underwear, where the comfort of the wearer is a top priority. The print does not create bulky or stiff labels, ensuring a smooth feel against the skin. - Eco-Friendly Inks:

Modern pad printing uses eco-friendly, water-based inks that comply with environmental standards. This makes pad printing a sustainable choice for manufacturers looking to meet consumer demand for eco-conscious products, especially in the fashion and textile industry. - Customization and Flexibility:

Pad printing offers high flexibility in terms of design. It allows for the printing of logos, brand names, and detailed wash care instructions in multiple colors, catering to the branding needs of clothing manufacturers. The ability to print directly onto the fabric without the need for additional labels offers greater design freedom and reduces material waste.

Compared to traditional sewn fabric labels, pad printing machines offer several distinct advantages when used for printing wash care labels on T-shirts and underwear:

- Cost Efficiency:

- Pad Printing: No need for additional fabric, sewing processes, or labor costs. The printing is done directly on the fabric, saving on material costs and production time.

- Sewn Fabric Labels: Requires extra materials such as fabric, thread, and needles, and labor for sewing, increasing production costs and time.

- Production Efficiency:

- Pad Printing: Allows for fast, bulk printing, ideal for mass production, with minimal manual intervention, making it highly efficient.

- Sewn Fabric Labels: Each label needs to be sewn individually by hand or machine, which is slower, especially in large-scale production, making it less efficient.

- Comfort:

- Pad Printing: The printed label is very thin and directly on the fabric, not affecting the comfort of the garment. There is no noticeable label feel when wearing.

- Sewn Fabric Labels: Sewn labels can cause discomfort, especially in intimate apparel like underwear, where the label may irritate the skin.

- Durability:

- Pad Printing: Modern eco-friendly inks used in pad printing are typically durable, resistant to water and wear, and less likely to fade or peel during washing.

- Sewn Fabric Labels: While fabric labels are generally durable, the sewing thread may loosen or break over time, causing the label to detach during washing.

- Design Flexibility:

- Pad Printing: Can print complex designs, logos, and fine text with high precision, even on irregular surfaces, offering greater design freedom.

- Sewn Fabric Labels: Designs are usually limited to the size and shape of the fabric label, and can only print simple text or graphics, offering less design flexibility.

- Environmental Friendliness:

- Pad Printing: Uses eco-friendly inks that comply with green standards, reducing waste and harmful chemicals.

- Sewn Fabric Labels: The fabric and sewing materials used may not be as environmentally friendly, especially if synthetic fibers or non-compliant materials are used.

- Aesthetic Appeal:

- Pad Printing: The printed design is smooth and precise, with clear text and graphics, resulting in a more polished and attractive visual appearance.

- Sewn Fabric Labels: The sewing lines may affect the garment’s appearance, and the label may not be as neat, leading to a less refined visual effect.

In summary, tagless pad printing machine offer higher production efficiency, lower costs, better comfort, environmental benefits, and greater design flexibility compared to traditional sewn fabric labels, making them a preferred method for label printing in the modern apparel industry.

DSTAR machine

DSTAR machine

WeChat

Scan the QR Code with wechat