Introduction

Printing technologies have come a long way, offering a variety of options for transferring images and designs onto various surfaces. Three popular methods in the world of printing are Pad Printing, Screen Printing, and Digital UV Printing. Each of these techniques has its unique characteristics, advantages, and applications. In this article, we will compare and contrast these printing methods, highlighting their differences and respective strengths.

Pad Printing is a versatile printing method that involves transferring an image from a silicone pad to a surface. It is commonly used for printing on irregularly shaped or curved objects, such as golf balls, electronics, and medical equipment. The process includes the following steps:

Advantages of Pad Printing:

- Versatility: Pad printing is ideal for printing on three-dimensional objects, making it suitable for items with irregular shapes.

- Fine Detail: It can achieve intricate designs and small text with high precision.

- Multi-Color Printing: Pad printing can handle multi-color printing with ease, allowing for vibrant and detailed graphics.

- Durability: The prints are known for their durability and resistance to wear and tear.

Screen Printing, also known as silk screening, involves transferring ink through a fine mesh screen onto the printing surface. It is a popular choice for textiles, signage, and promotional items. The process entails the following steps:

Advantages of Screen Printing:

- High Quality: Screen printing offers excellent color saturation and vibrancy, making it suitable for bold and vibrant designs.

- Cost-Effective for Large Runs: It is cost-effective for large print runs, making it a preferred choice for bulk orders.

- Versatility: It can be used on a wide range of substrates, including fabrics, paper, plastic, and more.

- Longevity: Screen prints are known for their durability and resistance to fading.

Digital UV Printing is a modern printing method that uses ultraviolet (UV) light to cure inks immediately upon contact with a substrate. This technology is often employed for signage, labels, and customized packaging. The process consists of the following steps:

Advantages of Digital UV Printing:

- High Resolution: Digital UV printing provides exceptionally high-resolution prints, perfect for detailed graphics and photography.

- Quick Turnaround: It is a fast printing process since there is no need for drying time.

- Variable Data Printing: Digital UV printing can easily handle variable data, making it suitable for personalized items.

- Environmentally Friendly: UV printing typically uses eco-friendly inks that do not emit harmful solvents.

Comparison and Conclusion

In summary, Pad Printing, Screen Printing, and Digital UV Printing are three distinct printing techniques, each with its unique strengths and applications. Pad printing excels in its ability to print on irregular surfaces with precision and durability. Screen printing is a cost-effective choice for large print runs, providing bold and vibrant colors. Digital UV printing stands out with its high-resolution output, quick turnaround, and environmentally friendly inks. The choice of which method to use depends on the specific requirements of a project, including the type of substrate, the desired image quality, and the quantity of prints needed. By understanding the differences and advantages of these printing methods, businesses and individuals can make informed decisions to achieve the best results for their printing projects.

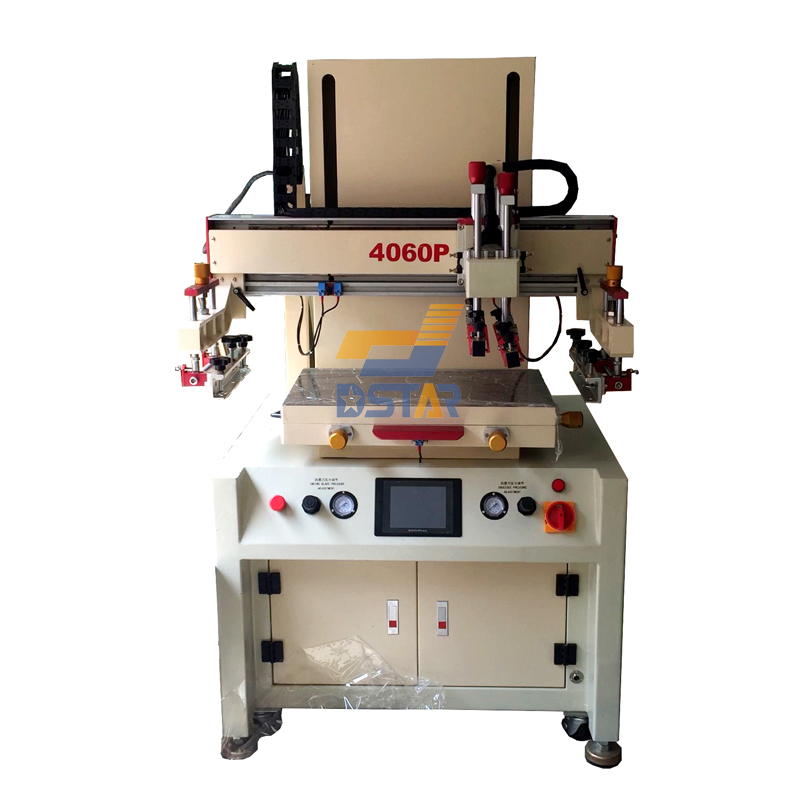

DSTAR machine

DSTAR machine

WeChat

Scan the QR Code with wechat