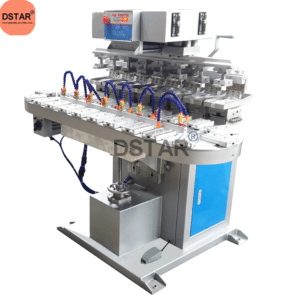

8 color tampo printing machine for plastic toys

Product:8 color tampo printing machine

Model:DX-SM8S-90

Brand:DSTAR

Printing color:1-8 color

Printing plate size:100*250mm

Ink cup size:90mm

Air supply:5-7bar

Machine size:L150*W96*H150cm

N.W:450KGS

Power:AC220V/2KW/1 Phase

- Slidding shuttle drive with servo motor

- 8 pcs silicone pad up and down independental with pneumatic drive

- Fixture platform with 2 axis servo rotatation.

- Independental ink cup forward and backward movement

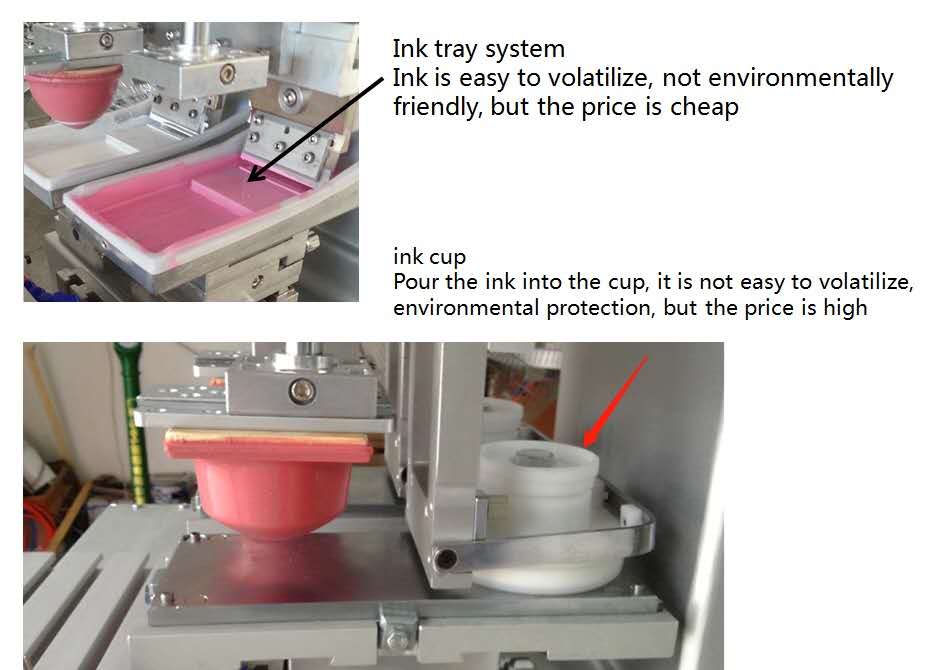

- Sealed ink cup system to be environmental and save ink

- Panasonic PLC system and SMC pneumatic components

A tampo printing machine, also known as a pad printing machine or tampon printing machine, is a specialized piece of equipment used for pad printing. Pad printing is a versatile and widely used process for transferring 2D images onto 3D objects. Tampo printing is commonly employed in industries such as automotive, electronics, medical devices, and promotional products. Here’s an overview of how a typical tampo printing machine works:

how a typical tampo printing machine works?

Loading Station:

- Objects to be printed (e.g., plastic parts, electronic components, promotional items) are loaded onto a fixture or conveyor system.

Ink Cup and Cliché Setup:

- The machine has an ink cup containing a pool of ink, and a cliché, which is a metal or polymer plate engraved with the desired image or pattern.

- The cliché is coated with ink, and excess ink is removed by a doctor blade, leaving ink only in the engraved areas.

Transfer Pad:

- The heart of the tampo printing process is the transfer pad, often made of silicone rubber. This pad picks up the ink from the cliché.

Printing Process:

- The transfer pad moves from its initial position to the ink cup, picking up the ink as it compresses against the cliché.

- The pad then moves to the object to be printed, and the ink is transferred from the pad to the object. The pad’s flexibility allows it to conform to the shape of the object, making it suitable for irregular surfaces.

Drying or Curing:

- Depending on the ink used, the printed objects may pass through a drying or curing station to ensure the ink adheres properly and dries quickly.

Automatic Unloading:

- In some setups, an automatic unloading system may be integrated to remove the printed objects from the machine.

Conveyor System:

- A conveyor system or other material handling mechanism transports the objects through the different stages of the printing process.

Control System:

- The machine is typically controlled by a computerized system that manages the movement of the pad, timing, and other parameters to ensure accurate and consistent printing.

Tampo printing machines are highly customizable and can accommodate various shapes, sizes, and materials. They are designed to provide high-quality and precise printing on a wide range of products. The specific features and capabilities of tampo printing machines may vary depending on the manufacturer and the intended application.

DSTAR machine

DSTAR machine

WeChat

Scan the QR Code with wechat