screen printing plate for all screen printing machine

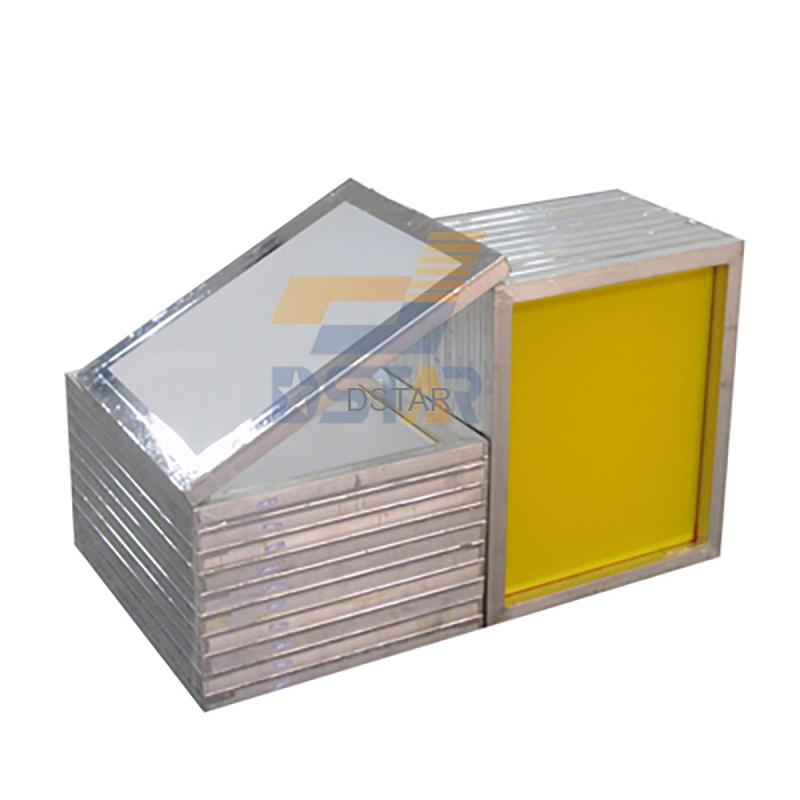

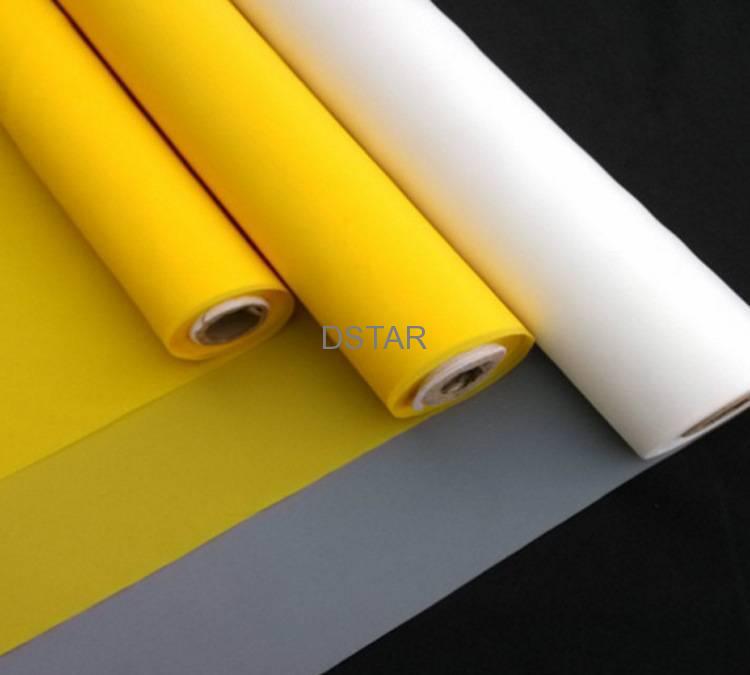

The screen printing plate is made by frame and polymer mesh.The frame material can be wood or aluminum.There are many sizes mesh for different printing requirements.

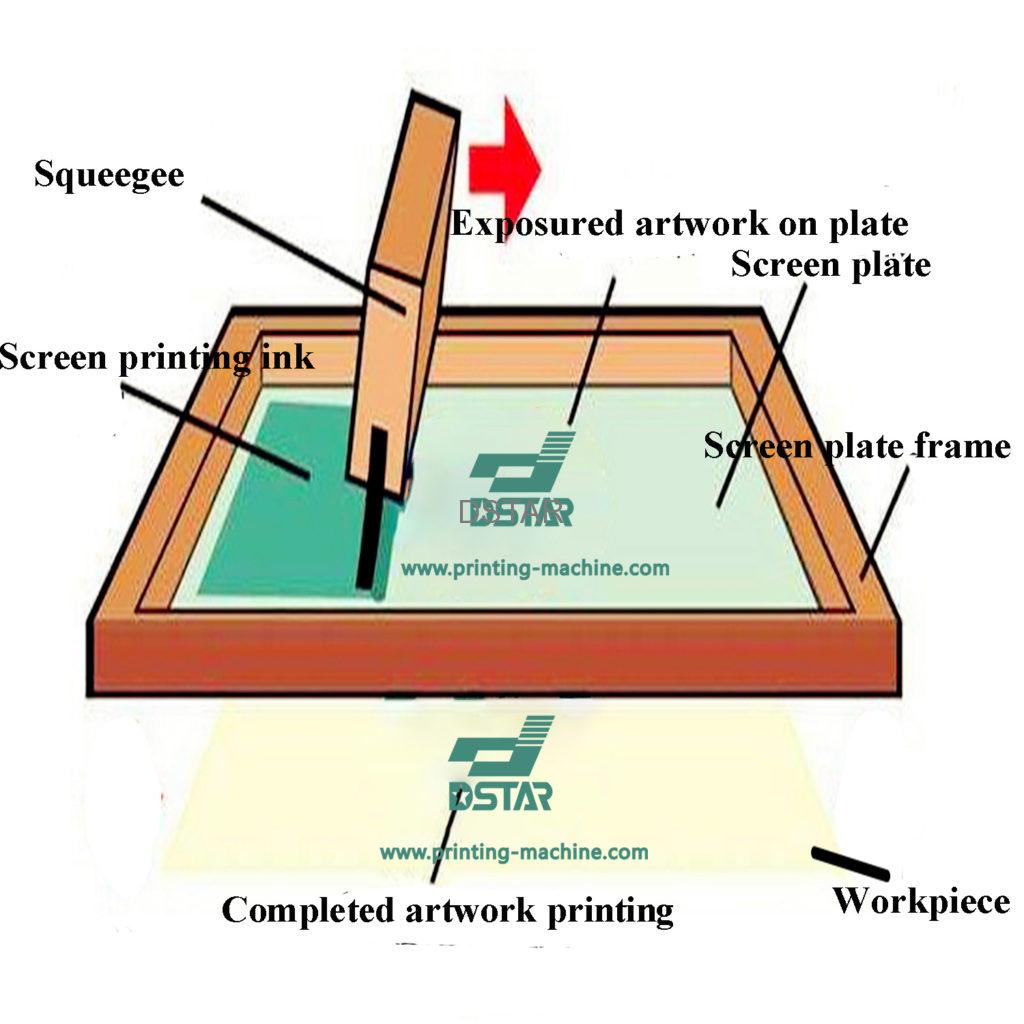

Screen printing refers to the use of silk screen as a plate base, and through the photosensitive plate making method, made into a printing plate with pictures and texts. Silk print consists of five major elements, screen print plate, squeegee, ink, printing table and substrate. Use the basic principle that the mesh of the graphic part of the printing plate can penetrate the ink, and the mesh of the non-graphic part cannot penetrate the ink for printing. When printing, pour ink on one end of the plate, use a scraper to apply certain pressure to the ink position on the printing plate, and at the same time move to the other end of the screen print plate at a uniform speed, the ink is moved by the scraper from the image and text Part of the mesh is squeezed onto the substrate.

Detailed explanation of the screen plate production process

Generally speaking, the production process of the screen production is different due to the different photosensitive materials used, but no matter which process is adopted, the following steps are indispensable in the screen production process: screen and frame selection, drawing, Washing the screen, coating photosensitive materials, exposing, developing and drying.

Let’s take a closer look at the operation methods and precautions of each process.

- The choice of screen mesh

At present, there are many types of screens on the market, such as silk screens, nylon screens, polyester screens, metal screens, etc. Generally, in terms of cost and applicability, nylon screens are the most commonly used screens on the market.

Introduction to the characteristics of nylon mesh

Nylon wire mesh has a smooth surface, good ink permeability, good softness, high elasticity, strong adaptability, good tensile strength, elasticity and friction resistance, large nodule fastness, long service life, acid resistance, chemical resistance and organic resistance. Solvent performance and many other characteristics, so it is favored by fine printing, and is widely used in fine line drawing patterns and dot printing.

Precautions for use:

In addition to the above advantages, nylon mesh also has some disadvantages, such as high elongation and low heat resistance. Therefore, the following points should be paid attention to when using nylon mesh:

·Due to the high elongation of nylon screen, it is required to use a strong screen frame and stretcher during printing;

·In view of the shortcomings of low heat resistance of nylon screens, do not use hot melt method to fix the screens during printing;

·Ultraviolet rays will also have some influence on nylon mesh, so you should avoid light when storing nylon mesh or its corresponding screen.

- The choice of screen frame

According to the material, the screen frame generally has six types: wooden frame, aluminum frame, iron frame, plastic frame, stainless steel frame and copper frame. Commonly used are wooden frame, aluminum frame, iron frame and so on.

·Wooden frame: relatively cheap and easy to make. It can be stretched manually or mechanically, but its shortcomings are that the strong charge is low, and it is easy to deform. It is only suitable for printing of low-precision products, not for fast and high-precision webs. In addition, NetEase pulled out of the wooden frame is slack and has poor recyclability.

·Iron frame: Compared with the wooden frame.It has the characteristics of stable size, sturdiness and durability, but its weight, easy to rust, and inconvenient to use, and can only be used to stretch the net mechanically.

·Aluminum frame: Although it is only suitable for mechanical stretching of the screen.it has the characteristics of small deformation, light volume, not easy to rust, and easy to move. Therefore, the aluminum frame is currently the most used screen frame in printing plate making.

Second, pull the net

In general plate making, the method of drawing the screen can be divided into three types: manual, mechanical and pneumatic. For example, the screen printing factory does not require high precision, generally the first two methods are used; if the requirements are higher, the last A pneumatic stretching machine, which is suitable for high-precision screen drawing. It is characterized by uniform tension, easy to use, and can reach different needs of the screen tension. It is especially suitable for drawing high-precision printing screens for color printing.

Three, wash the net

When printing plates, special chemicals are generally used to wash the screen (such as stripping water, thinner, detergent, etc.).but this method is time-consuming, so for those processing plants that pay attention to aging, this method is slightly more obvious Trouble.here is an effective method to share with you. choosing a detergent with strong detergency, such as Tide, wetting the screen, and then sanding it with cotton cloth. This method removes the dirt quickly, and is also conducive to the adhesion of the photosensitive glue. Attached, it can be described as one sword and two swords. (Note: For the above method, double-sided sanding is required when sanding. When sanding the front side, the force needs to be lighter to prevent the net from falling off.) After washing the net, put the net in the dryer to dry for later use.

DSTAR machine

DSTAR machine

WeChat

Scan the QR Code with wechat