Printing machine for rubber ball

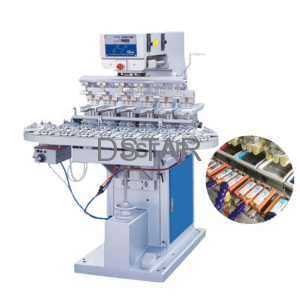

Product:printing machine for rubber bouncy ball

Model:DX-SB6C-90

Brand:DSTAR

Printing color:1-6 color

Printing plate size:100*250mm

Ink cup size:Dia90mm

Oval belt conveyor fixture stations:18

Machine size:L120*W120*H150cm

N.W:395KGS

Power:AC220V/1P/1500W

The Printing Machine for Rubber Bouncy Balls is a state-of-the-art device designed to elevate the customization and efficiency of printing on spherical surfaces. Employing pad printing technology, this machine offers the capability to print one to six colors on each bouncy ball, providing a versatile and vibrant printing solution.

Rubber ball printing samples

Machine features

1. Pad Printing Technology:

Utilizing the pad printing process, this machine ensures precise and detailed printing on rubber bouncy balls. This method is renowned for its ability to transfer intricate designs onto curved and irregular surfaces, making it ideal for spherical objects like bouncy balls.

2. Multi-Color Printing:

With the capacity to print up to six colors, this machine allows for a diverse range of creative and customized designs on each bouncy ball. This feature caters to the demands of businesses and individuals seeking vibrant and eye-catching printed products.

3. Automatic 180-Degree Rotation:

The machine incorporates an automatic 180-degree rotation mechanism, ensuring a complete and uniform print coverage on the entire spherical surface of the bouncy ball. This rotational capability enhances efficiency and precision in the printing process.

4. Ink Cup scraping ink Structure:

Featuring an ink cup doctoring structure, the machine optimizes ink usage while maintaining environmental friendliness. This design minimizes ink wastage, contributing to cost-effectiveness and sustainability in the printing process.

5. Manual Loading, Automatic Multi-Color Printing, and Automatic Unloading:

The machine offers a user-friendly operation with a manual loading system, automated multi-color printing process, and automatic unloading functionality. This combination of manual and automatic features streamlines the production process, making it efficient and accessible for various users.

Conclusion:

In conclusion, the Printing Machine for Rubber Bouncy Balls is a technologically advanced solution for achieving high-quality and colorful prints on spherical surfaces. Its adoption of pad printing, multi-color capabilities, automatic rotation, and eco-friendly ink cup structure make it a versatile and sustainable choice for businesses engaged in the production of custom-printed rubber bouncy balls.

DSTAR machine

DSTAR machine

WeChat

Scan the QR Code with wechat