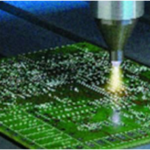

Plasma printing pretreatment equipment

Voltage:AC220( ±10% ) Vac 50/60Hz,

Fuse:10A/250V

Output power:1000W

Power consume:≤1100

Air supply:0.05MPa~0.5MPa (0.5Kg~5Kg)

Frame size:W183*H 420*L480mm

N.W:15Kg

Plasma treat n.w:5kg

plasma treatment height:5-15MM

What’s Plasma?

When the matter receives energy, it will change from solid state to liquid state, and then from liquid state to gas state. The gas molecules excited by a strong energy will ionize and transform into another state of gas aggregation, that is, the plasma state. When high-energy plasma bombards the surface of other substances, chemical and physical reactions will occur, resulting in some beneficial functional applications.

Plasma Application:

Plasma treatment of the surface of the material basically has the following major effects:Activation: greatly improve the surface wetability and form an active surface; Cleaning: remove dust and oil, fine cleaning and anti-static;Coating: through surface coating treatment, Provide a functional surface; improve surface adhesion, improve the reliability and durability of surface adhesion.After treatment with atmospheric pressure plasma technology, the surface energy of all kinds of polymer plastics, ceramics, glass, PVC, paper or metal can be improved. Through such a treatment process, the surface tension characteristics of the product material are improved, and it is more suitable for industrial processing requirements such as coating and bonding. For example, in electronic products, the coating treatment of LCD screens, the surface spraying screen printing of structural parts such as casings and button buttons, the de-gluing and decontamination cleaning of the PCB surface, the treatment before lens glue sticking, the treatment of wires and cables before coding …and many more. Treatment before pasting of lampshades, brake pads, and door seals in the automobile industry; subtle and harmless cleaning treatment of metal parts in the machinery industry, treatment before plating of lenses, treatment before bonding and sealing between various industrial materials… etc. The processing before gluing the edge-sealing position in the printing and packaging gluing machine,…etc. In the medical device industry, the treatment of needles and plastic catheters before bonding, etc

Auto parts plasma pretreatment

PCB plasma pretreatment

LED plasma pretreatment

Electronics plasma processing

PP/PE material plasma pretreatment

Metal material plasma processing

DSTAR machine

DSTAR machine

WeChat

Scan the QR Code with wechat