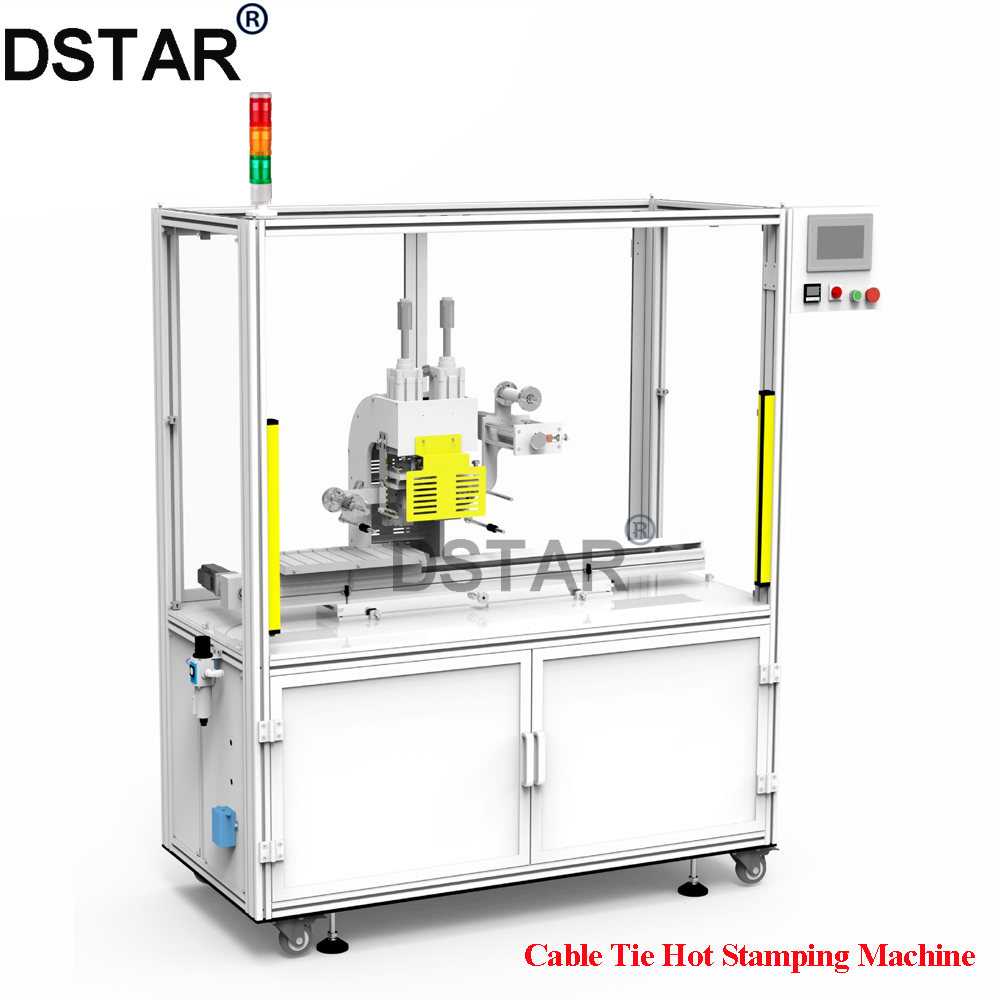

Automatic nylon cable tie hot stamping machine

Product:Nylong cable tie hot stamping machine

Model: DX-ZDH2

Power: 1200W

Speed: 30~40times/min

Printing area: Custom made

Gross weight:400KGS

Package size: L1800*W800*H1780mm

Hot stamping is a preferred method for applying branding and other information to cable ties for several reasons:

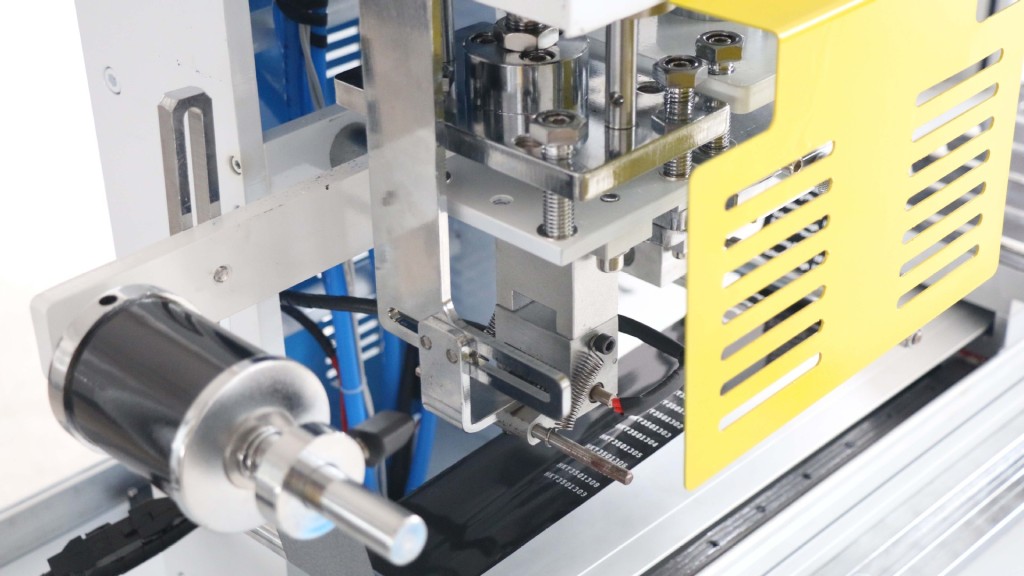

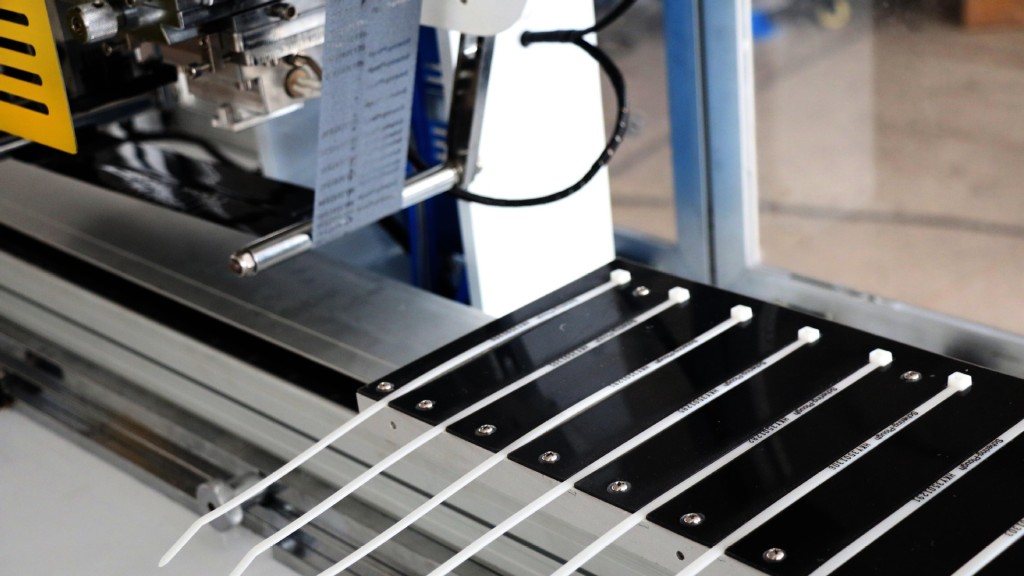

- Durable and Long-Lasting: Hot stamping creates a permanent bond between the foil and the nylon material, resulting in a durable and long-lasting mark. This is crucial for cable ties that will be subjected to various environmental conditions, including exposure to UV light, moisture, and temperature fluctuations.

- Cost-Effective: Hot stamping is a cost-effective solution for marking cable ties, especially when compared to other methods like laser marking or printing. It requires relatively simple equipment and can be performed quickly, making it suitable for high-volume production.

- Versatility: Hot stamping allows for a wide range of foil colors, finishes, and effects, giving manufacturers the flexibility to create visually appealing and customized cable ties. This versatility is especially valuable for branding and product differentiation.

- High-Quality Appearance: The hot stamping process results in a clean and precise mark on the cable ties. It provides a professional and high-quality appearance, making the cable ties more attractive to customers and end-users.

- Easy to Implement: Hot stamping is a straightforward process that can be integrated into existing cable tie production lines with minimal disruption. Once the hot stamping machine is set up and calibrated, it can operate efficiently with minimal maintenance.

- Speed and Efficiency: Hot stamping is a fast process, allowing manufacturers to produce cable ties with stamped information quickly. This is essential for meeting tight production schedules and fulfilling customer orders promptly.

- Compatibility with Various Materials: Hot stamping can be used on a wide range of materials, including different types of nylon commonly used for cable ties. This versatility ensures that manufacturers can apply hot stamping to various cable tie models.

- Eco-Friendly: Unlike some other printing methods that may involve solvents or chemicals, hot stamping is a relatively eco-friendly process. It does not release harmful emissions into the environment and generates minimal waste.

Overall, hot stamping offers a practical and efficient solution for marking cable ties, providing manufacturers with a reliable method to enhance their products’ branding and identification capabilities.

1.product size

2.printing area size

3.product materials

4.capacity requirements

Thanks for your sharing in advance.

Error: Contact form not found.

DSTAR machine

DSTAR machine

WeChat

Scan the QR Code with wechat