Ink cups 60B-TSB1 for pad printer machines

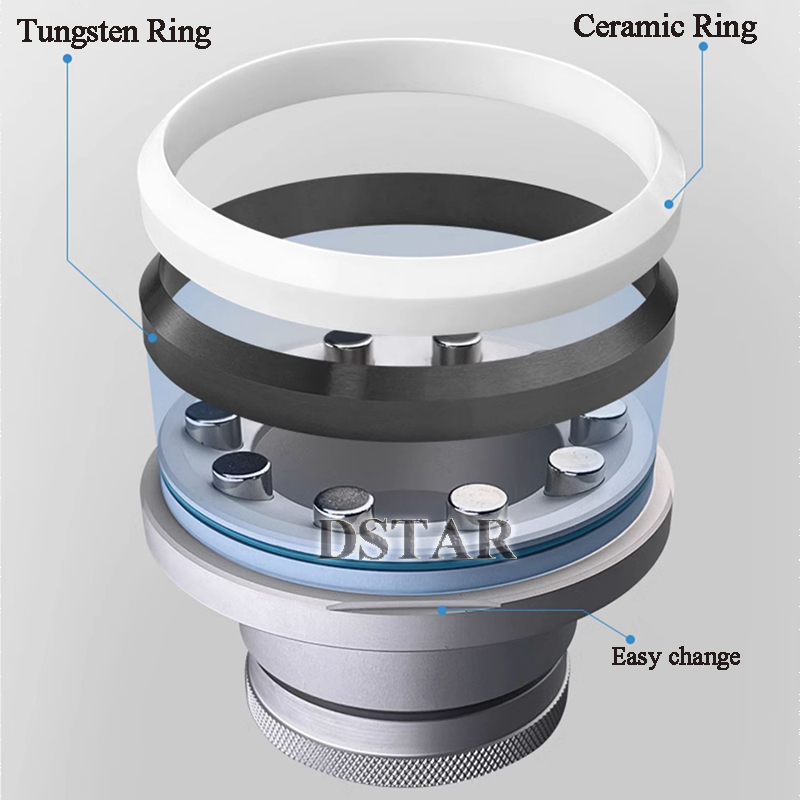

| Model | Ink cup ring material | Ring size | Cup body material | Ring bevel | Bevel Type |

| 53A-CSB1 | Ceramic | φ60*φ53*12mm | Aluminum | Single | B1 |

| 53A-TSB1 | Tungsten(Carbide) | φ60*φ53*12mm | Aluminum | Single | B1 |

| 58A-CSB1 | Ceramic | φ65*φ58*10mm | Plastic | Single | B1 |

| 60A-CSB1 | Ceramic | φ65*φ60*5.2mm | Plastic | Single | B1 |

| 60A-TSB1 | Tungsten(Carbide) | φ65*φ60*5.2mm | Plastic | Single | B1 |

| 60B-CSB1 | Ceramic | φ70*φ60*12mm | Aluminum | Single | B1 |

| 60B-TSB1 | Tungsten(Carbide) | φ70*φ60*12mm | Aluminum | Single | B1 |

| 70A-CSB1 | Ceramic | φ80*φ70*12mm | Aluminum | Single | B1 |

| 70A-TSB1 | Tungsten(Carbide) | φ80*φ70*12mm | Aluminum | Single | B1 |

| 82A-CSB1 | Ceramic | φ90*φ82*12mm | Aluminum | Single | B1 |

| 82A-SSB1 | Tungsten(Carbide) | φ90*φ82*12mm | Aluminum | Single | B1 |

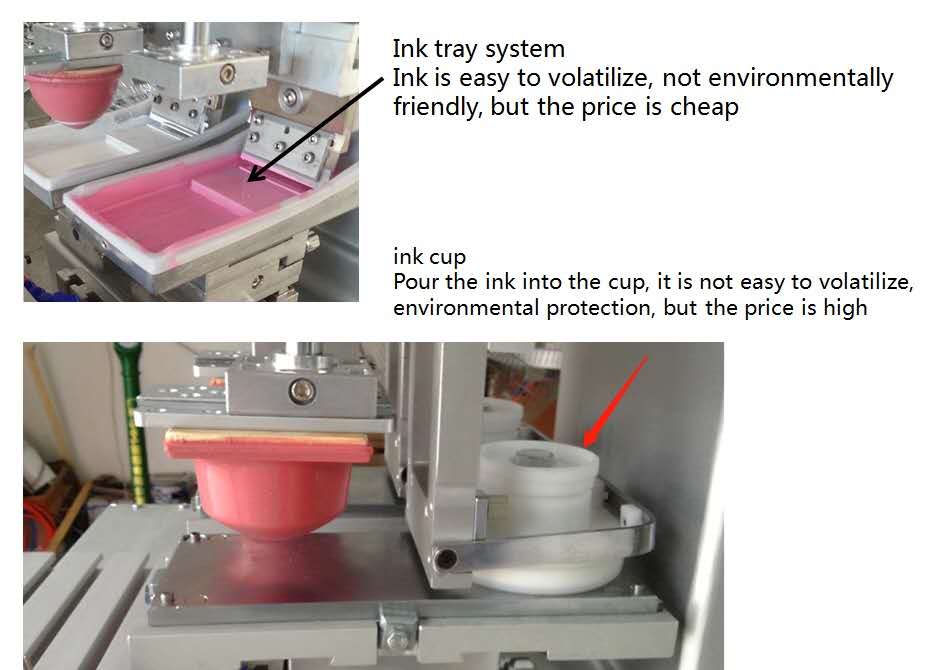

What’s the advantage of pad printer with ink cups?

Pad printers with ink cups and those with open ink wells both serve the purpose of transferring ink from a plate onto a substrate through a silicone pad. However, they differ in their mechanisms and have distinct advantages:

- Ink Containment: Ink cups enclose the ink, preventing it from drying out or being exposed to contaminants like dust or debris. This containment helps maintain ink consistency and quality over time, leading to better print results and reduced waste. Open ink wells are more susceptible to evaporation and contamination, requiring frequent replenishment and maintenance.

- Ink Efficiency: Ink cups typically use less ink compared to open ink wells since they only expose a small portion of ink to the air during printing. This efficiency can result in cost savings over time, especially for high-volume printing operations.

- Cleaner Operation: Ink cups minimize the risk of spills and splatters, leading to cleaner printing environments and reducing the need for cleanup. This cleanliness can improve overall productivity and reduce downtime associated with maintenance tasks.

- Versatility: Ink cups allow for quicker color changes since they can be easily swapped out, making them ideal for printing jobs that require frequent color changes or customization. Open ink wells may take longer to clean and refill between color changes, limiting their efficiency in such scenarios.

- Consistency: Ink cups provide more consistent ink coverage and transfer, resulting in uniform prints with minimal variation. This consistency is particularly important for applications requiring precise detail or multi-color registration.

In summary, pad printers with ink cups offer advantages in ink containment, efficiency, cleanliness, versatility, and consistency compared to those with open ink wells. However, the choice between the two depends on factors such as printing volume, job requirements, and budget constraints.

1 color pad printer 1 color pad printing machine automatic hot stamping machine automatic pad printing machine bottle closure printing machine bottle screen printing machine cable tie hot stamping catheter pad printing machine Catheter printing machine China economy China printing machine China sea foreign trade Christmas ball printing machine coin printing machine cosmetic bottle printing cosmetic printing machine cup printing machine cup screen printing machine desktop pad printer drinking straw printing machine EXPO figure toy printing machine heel pad printing machine hot stamping machine LED bulb printing machine non woven bag printing machine pad printer machine pad printing pad printing ink pad printing machine pad printing plate pad printing technology perfume bottle printing machine pet cup printing machine PLA drinking straw printing machine printing ink Printing machine satin ribbon printing machine screen printing machine Shanghai port shoe heel printing machine silicone pad silicone pad for pad printing tampography machine watch dial printing machine

DSTAR machine

DSTAR machine

WeChat

Scan the QR Code with wechat