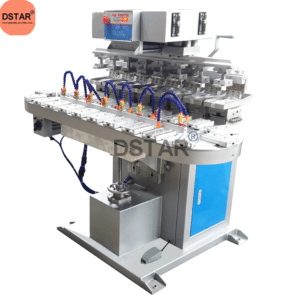

hard hat logo printing machine

Product:hard hat logo printing machine

Model:DX-SM8S

Printing color:8 color

Printing plate size:200*200mm

Ink scrap:open ink well

Fixture:1 axis rotation

Sliding shuttle:servo motor

Machine size:L180*W115*H150cm

hard hat pad printing machine is a specialized piece of equipment used to print logos, designs, or other custom artwork onto hard hats. This machine typically uses the pad printing process, a form of indirect offset printing, to transfer ink from a printing plate onto a curved or uneven surface, such as the surface of a hard hat. This method is well-suited for hard hats because it can handle the various shapes and materials that make up these safety helmets.

Key Components of a Hard Hat Pad Printing Machine

Printing Pad: The pad is made from silicone or rubber and is used to transfer the ink from the printing plate to the surface of the hard hat. It conforms to the shape of the surface being printed on, ensuring the design is applied uniformly.

Cliche (Printing Plate): The printing plate, or cliche, is a metal plate engraved with the design that will be printed onto the hard hat. The design is inked onto the plate, and the pad picks up the ink from the plate for transfer to the hard hat.

Ink Cup(for sealed ink cup scrap system only): This is a small container that holds the ink, which is applied to the cliche. The ink is typically specially formulated for durable, long-lasting prints on hard hats, which need to withstand harsh environments.

Hard Hat Fixture: A device or clamp that holds the hard hat securely in place while the printing process takes place. It may be adjustable to accommodate different sizes and types of hard hats.

Control System: This allows the operator to set the printing parameters, such as speed, pressure, and alignment, ensuring the desired print quality.

Advantages of Using a Pad Printing Machine for Hard Hats:

Versatility: It can print on curved, uneven, and irregular surfaces like hard hats.

Precision: Provides high-quality, detailed prints, even for small logos or intricate designs.

Durability: The ink used is often resistant to wear and tear, which is essential for hard hats that are exposed to harsh environments.

Efficiency: Capable of printing a large number of hard hats quickly and consistently, making it suitable for high-volume orders.

Applications

Customizing Hard Hats for Companies: Logos, safety instructions, or other branding elements can be printed on hard hats for safety and promotional purposes.

Personalization: Custom designs or identification numbers for individual workers.

Safety Markings: Printing of safety symbols or information for regulatory compliance

Choosing the Right Machine:

When selecting a hard hat pad printing machine, key factors to consider include:

- Print Area: The size of the print area that the machine can handle, especially when printing on curved or irregular surfaces like hard hats.

- Automation vs. Manual: Automated machines can be faster and more consistent, while manual machines may be more cost-effective for smaller runs or custom jobs.

- Ink Compatibility: Ensure that the machine works with inks designed for hard hats and that are durable enough for industrial environments.

- Production Volume: Some machines are built for high-volume printing, while others are more suitable for low-volume or custom work.

If you are looking to buy a hard hat pad printing machine, Shenzhen DSTAR Machine Co.,ltd is specialized in manufacturing this type of equipment, offering a range of models to suit different production needs.

DSTAR machine

DSTAR machine

WeChat

Scan the QR Code with wechat