DX-A4 photopolymer pad printing plate exposure machine

Model:DX-A4

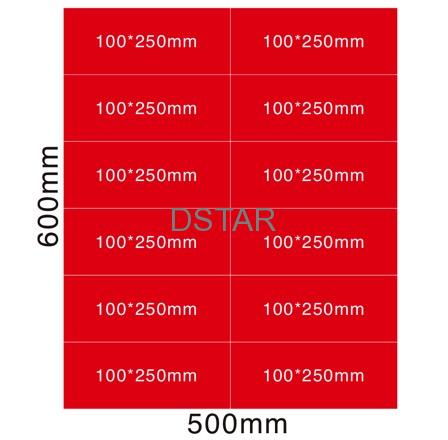

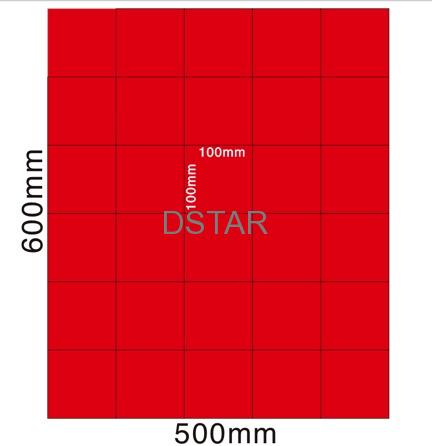

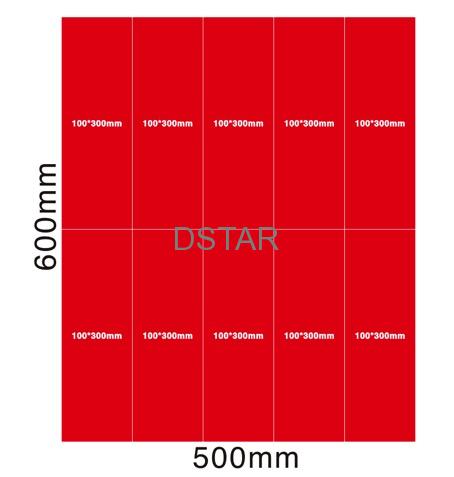

Exposure size:400*250mm

Exposure time:0-9999 secs

Washing time:0-9999 secs

Drying time:0-9999 secs

Power:AC220V/200W

N.W:50KGS

Size:L50*W40*H60cm

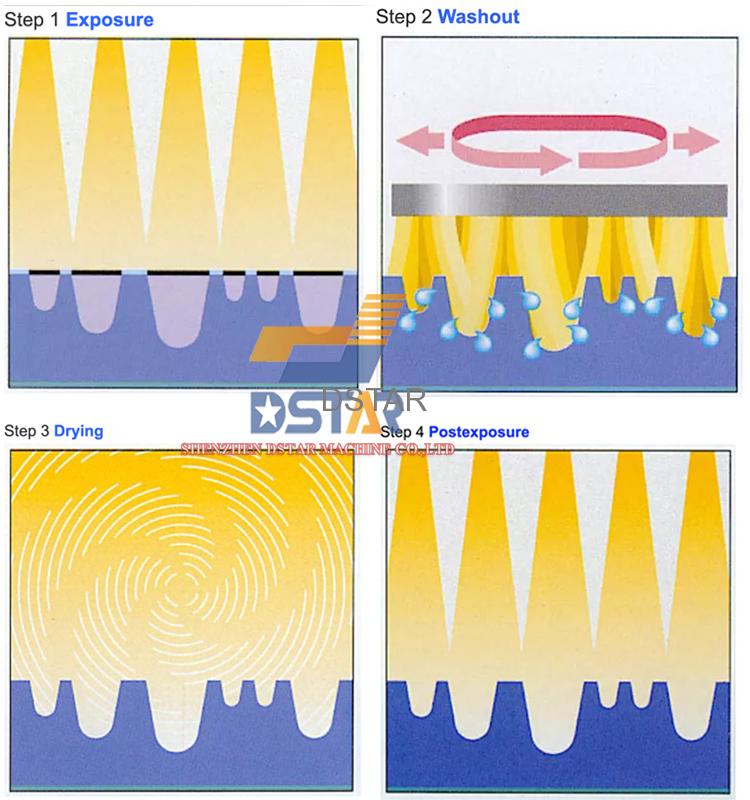

Step 1 Exposure

Remove the raw plate from its packaging, cut it to the required size with guillotine shears, place it on the vacuum plate of an exposure unit with the sensitised side upward and remove the protective foil.Depending on the printing (direct or indirect), place the non-reversed or reversed image positive film, matt face down, onto the plate, roll the vacuum foil over film and plate and activate the vacuum. If necessary, use a soft anti-static cloth or a foam squeegee to ease out any trapped air. After quickly checking the vacuum and closing the lid, start the exposure with the set time.

Step 2 Washout

After exposure, the exposed parts on the plate are visible by the change in colour.Depending on the equipment used for washout, the exposed plates are then mounted in the washer or in a flowline washer, attached to the flowline carrier (adhesive or magnetic plate) and washed out for the specified time.

Step 3 Drying

In the case of nylon print flow line washers (water) with an integrated dryer (DWT), the plate is already dried and post exposed when it leaves the unit. The cliché is ready for immediate use.When using a washer from the CW combination or a unit with a similar design, once the plate has been exposed,it must first be rinsed to remove any remaining washout solution (alcohol/water mix or water). The plate is then placed in the dryer and dried for the specified time at the specified temperature.It is important, for water-washable plates, that no residual water remains on the plates, as this could damage the relief layer and the relief adhesion when the plates are heated in the dryer.

Step 4 Post exposure

Once drying is complete, the plate is post exposed, so that all the elements that received little light during

exposure are adequately polymerised.Two minutes is sufficient time for post exposure

DSTAR machine

DSTAR machine

WeChat

Scan the QR Code with wechat