plastic cup screen printer machine

Product:disposal plastic cup screen printing machine

Model:DX-S101

Brand:DSTAR

printing color:1 color or multi color

Printing size:

Cylinder ¢20-100mm Height 25-300mm

Oval W25-120mm Height 25-300mm

Speed:cylinder 4,000pcs/hr

oval 5,000pcs/hr

Voltage:AC380V 3Phase

Power:Machine(1.5KW) UV(5KW)

Air supply:0.6Mpa

Gas:0.15Mpa

Machine size:L200*W100*H150cm

N.W:1000KGS

Disposal cup printing samples

About disposal plastic cup screen printing machine

Plastic cups offer customers an affordable and efficient way to market their brand at an event or meeting.No need to consider the pretreatment for keeping ink adhesion on plastic cup due to short life as disposal products.It will not go in dish washer for repeated use.

The ink you decide to use will depend on your throughput and budget. If you are purchasing a T8-SS with integrated UV, you will be using UV inks which are easiest to work with as they do not dry to the screen unless left out with the light on over head (best to cover screen between uses).Solvent based inks may be used and you can air dry them or expose them to forced air and IR to expedite the drying. UV provides you with an instant cure for your products so they can immediately go into packaging.

Using solvent inks may take a few minutes to a few hours depending on if you are air curing or using forced hot air/ IR.When you are looking at tooling to use for placing your plastic cups on prior to printing,it is important to make sure the tolerance for the sizes of cups you receive are made known by the manufacturer for your machine. You need your plastic cup to be hugging the fixture it is placed on for optimal prints and avoid any tooling that will affect the form of the plastic cup when the screen is moved down and the squeegee pushes the ink through the screen on the part. If there is space for the cup to bend, your image will be compromised. SA offers precision manufacturing and we will show you that the machine works prior to shipping through test print videos using your product Plastic cups range in their thickness.

If you are using a thin plastic cup that is typically used for parties and one time uses, it is advised you do not use forced hot air to cure your products to avoid any warping that may occur. Conventional UV curing may also cause warping but this can be mitigated by opting for UV LED. SA systems that use conventional UV are designed with your ability to control the amount of UV that your cup is exposed to and the time it is exposed for. We will work with you on finding the process best for your product.

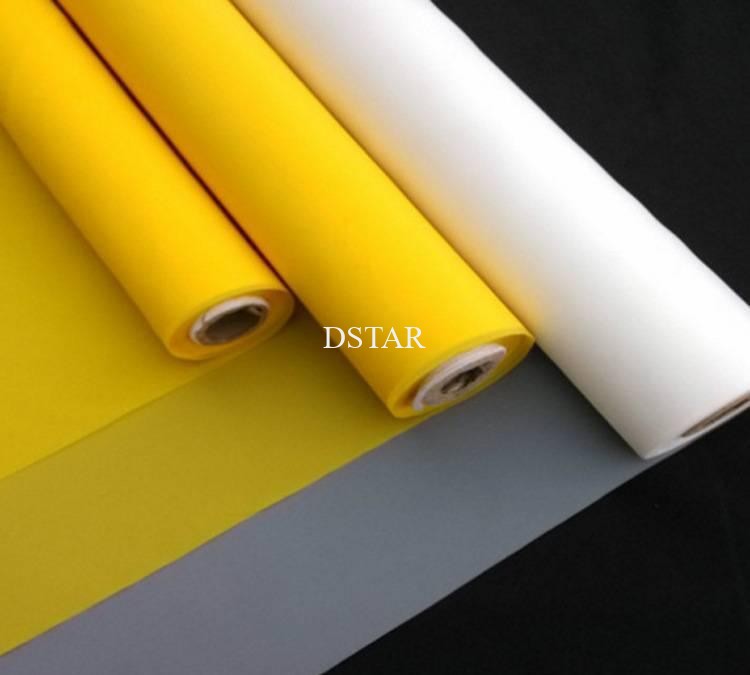

Plastic cup screen printing spare parts

- Squeegee

- Screen printing plate

- Printing ink and ink solvent

- Cup fixture

Machine video

DSTAR machine

DSTAR machine

WeChat

Scan the QR Code with wechat