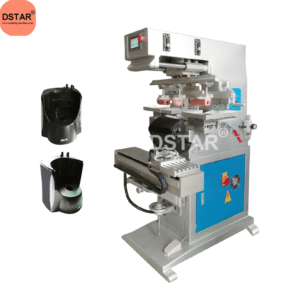

Automatic hot stamping machine for bottle closure DX-AHM

The Automatic Hot Stamping Machine for plastic bottle closure is an automatic equipment for decorating process on plastic closurees. This innovative machine combines precision engineering with advanced technology to deliver consistent and high-quality results.

Key Features:

- Automated Operation: The machine is equipped with state-of-the-art automation technology, allowing for efficient and streamlined operation. This not only increases productivity but also ensures a uniform and professional finish on every plastic lid.

- Hot Stamping Technology: Utilizing hot stamping technology, the machine imprints a brilliant gold border onto plastic lids. This process not only imparts a premium aesthetic but also adds a layer of sophistication to the product.

- Versatility: The machine is designed to handle a variety of plastic lid sizes and shapes, providing flexibility for manufacturers with diverse product lines. It can accommodate different materials and surface finishes, making it adaptable to various packaging requirements.

- User-Friendly Interface: Featuring an intuitive and user-friendly interface, the machine is easy to operate and allows for quick setup. Operators can control stamping parameters and monitor the process with ease, contributing to a smooth production workflow.

- High Precision and Consistency: The Automatic Plastic Lid Gold Stamping Machine ensures high precision in the stamping process, resulting in consistent and uniform gold borders on each plastic lid. This precision is crucial for meeting quality standards and satisfying customer expectations.

- Durable Construction: Built with durability in mind, the machine is constructed from robust materials to withstand the rigors of industrial use. This ensures a long operational life, minimizing downtime and maintenance costs.

- Cost-Efficiency: By automating the gold stamping process, the machine contributes to cost savings by reducing manual labor requirements and improving overall production efficiency. This makes it an economically viable investment for manufacturers seeking to enhance the visual appeal of their plastic lids.

In summary, the Automatic Hot Stamping Machine is an excellent proposal for manufacturers looking to elevate the visual impact of their plastic lids. With its advanced features, precision engineering, and user-friendly interface, this machine offers a reliable and efficient way to incorporate luxurious gold borders, adding value to the final product.

DSTAR machine

DSTAR machine

WeChat

Scan the QR Code with wechat