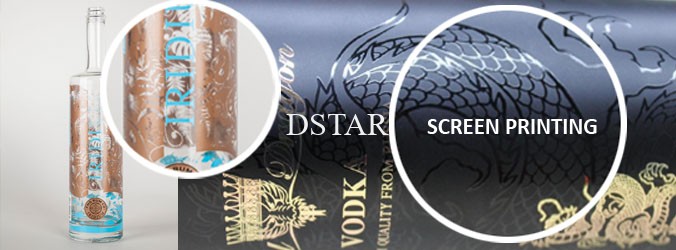

how to do glass bottle screen printing?

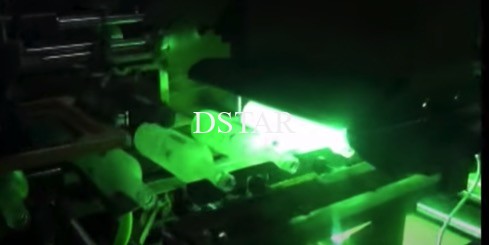

Product:automatic glass bottle screen printing machine for sale

Model Number: DX-GS103

Brand:DSTAR

Usage: glass bottle screen printing

Automatic Grade: Automatic

Printing color: Multi color

Voltage: 220V, 1P

Power: 2.8KW

Machine size(L*W*H): 2900*1200*1800mm

N.W: 800kgs

Certification: CE

Warranty: 1 Year

After-sales Service Provided: Engineers available to service machinery overseas

Application: glass bottle printing(UV ink,glass glaze)

Then,How to do screen printing on glass?

Screen printing flat glass glazes are typically 240 mesh, with 220 mesh being the most popular screen printing mesh for glass screen printing.

The glass printing screen is identical to the screen used for traditional screen printing.The type of silkscreen cloth to choose is vary from the printing purpose. For highly accurate fine glass goods, a mesh count of 300 to 360 mesh is necessary. Polyester and nylon synthetic mesh can be utilized for infrared hot stamping glaze printing.Because it is cost effective for a limited amount of glass screen printing types, this form of screen printing is widely utilized.

Below are the steps to use to fulfil the screen printing on glass.

1.Create a Design

To begin, print the design they wish to appear on the completed product onto a clear acetate film. Now, as you choose this design, you need to have in mind the glass bottle design as well. This helps you to not only create a design of your choice, but also the one that suits your product’s bottle.

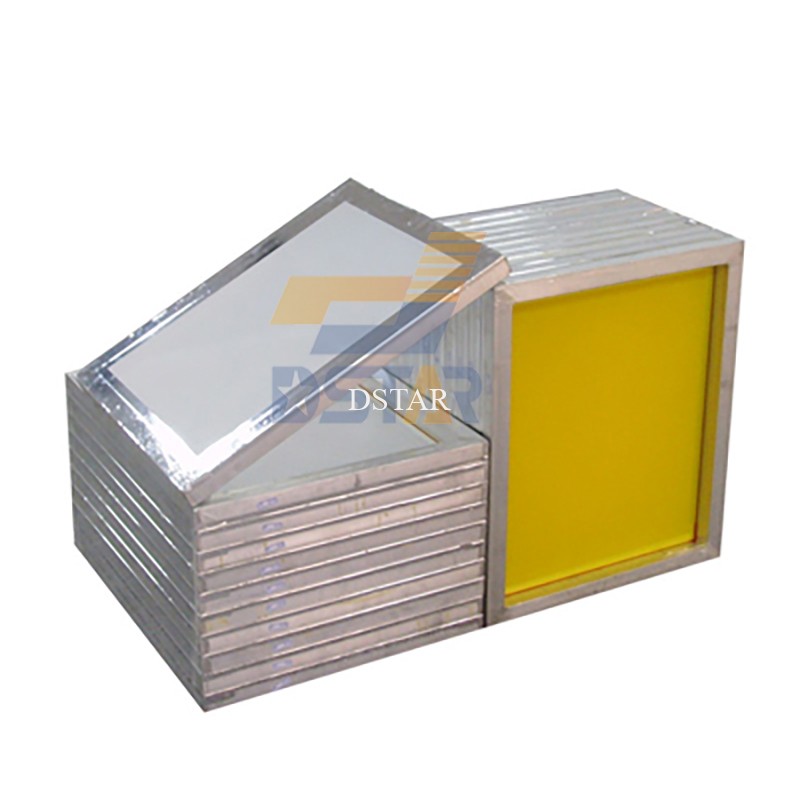

2.Prepare the Screen

Now, select a mesh screen based on the design’s intricacy as well as the thickness of the glass being printed.After that, a coating of light-reactive emulsion is for the mesh screen,which hardens when exposed to bright light.

3.Expose the Emulsion

The design is subsequently transferred from the acetate sheet to the emulsion-coated screen,which is then subjected to very strong light. Because the emulsion is hardened by light, the areas of the screen that are obscured by the design stay liquid.

If the final design includes more than one colour, each layer of ink must be applied using a distinct screen.To make multi-coloured goods, the printer must utilize his artistic ability to design each stencil and line them up properly to achieve a flawless final design.

4.Wash the Emulsion off, to Create the Stencil

The portions of the screen not concealed by the design will have hardened hard once the screen has been exposed for a certain amount of time. Any emulsion that hasn’t solidified needs to be carefully washed away. The design is clearly imprinted on the screen,allowing the ink to pass through.

After the screen has dried, you can perform any required changes to ensure that the imprint is as close to the original design as conceivable. The stencil is now complete and ready to use.

5.Prepare the Glass for Printing

Afterwards, the screen is then mounted on the printing press. Beneath the screen,the glass to be printed is positioned flat on the printing board.

Although there are manual and automatic presses, most current commercial printers will utilize an automatic rotating carousel printer(so you are free to do so by the way), which allows multiple separate screens to work at the same time. This type of printer may also be used to apply the various colour layers in rapid succession for multi coloured prints.

6.Press the Ink Through the Screen on the Glass

The screenis placed onthe printingboard and lowered. A squeegee is used to drag the ink along the whole length of the screenonce it has been applied at the top end. This forces ink thru the stencil’s exposed regions, impressing the design onthe glassbeneath.

You can lift the screenand place a fresh piece of glass onto the printingboard if you want to produce numerous pieces. After that, the procedure is repeated.

Remove the emulsion using a specific cleaning solution once all of the glasses have been printed and the stencil has served its function, so the mesh may be repurposed to make new stencils.

7.Dry Your Glass and Check Your Finished Work(also named ink curing)

After that, the printed glassis dried, which ‘heals’ the ink and gives it a smooth, colour fast surface. Before being passed onto its new owner, you should check the completed glass product, properly examine and clean it to eliminate any remnants.

- Printing squeegee

- Screen printing plate

- Printing ink and ink solvent

DSTAR machine

DSTAR machine

WeChat

Scan the QR Code with wechat