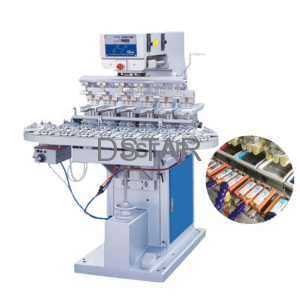

6 color Pad printing machine with servo drive

Product:6 color pad printing machine with servo drive

Model:DX-SM6S-90

Brand:DSTAR

Printing color:6 color

Printing plate size:100*250mm

Ink cup:φ90mm

Silicone pad F/B:servo drive

Slidding shuttle:Servo Drive

Fixture rotate and angle:Servo Drive

N.W:380KGS

Power:AC220V/2KW/1 Phase

Machine size:L100*W96*H150cm

In the realm of advanced printing technology, the 6-Color Pad Printing Machine with Servo Drive stands out as a cutting-edge solution. This machine incorporates servo drive technology to enhance precision and flexibility in the printing process. Let’s explore its key features:

Application of this machine

- Plastic panel,such as washing machine panel,office printer panel

- Plastic toys

- Injection product with multi sides printing

Key Features:

1. Independent Operation of Silicone Pads:

The distinguishing feature of this machine lies in the independent movement of silicone pads. Both vertical and horizontal motions are driven by servo technology, providing unparalleled control over the printing process and ensuring precise application.

2. Servo-Driven Silicone Pad Front-to-Back Movement:

The front-to-back movement of the silicone pad is also servo-driven, contributing to the overall precision and consistency of the printing operation. This advanced control mechanism guarantees accurate alignment and application of ink onto the printing surface.

3. Servo-Driven Shuttle Worktable:

To optimize efficiency, the shuttle worktable of the machine is powered by servo drives for both left and right movements. This not only accelerates the printing process but also ensures a smooth and reliable operation of the entire system.

4. Two-Axis Servo Rotation for Fixture Worktable:

The fixture worktable is equipped with a two-axis servo rotation system, allowing for the customization of product rotation angles. This adaptability is crucial for accommodating diverse printing requirements and ensuring the perfect alignment of prints on various surfaces.

5. Sealed Eco-Friendly Ink Cup Structure:

Addressing environmental concerns, the machine adopts a sealed ink cup structure, reducing ink consumption and minimizing the emission of volatile odors. This eco-friendly approach aligns with contemporary sustainability standards.

6. Panasonic PLC Control System:

The entire machine is governed by a Panasonic Programmable Logic Controller (PLC). This Japanese technology ensures precise control over all aspects of the printing process. Operators can conveniently monitor and adjust parameters and operational statuses using the 7-inch touchscreen interface.

Conclusion:

In summary, the 6-Color Pad Printing Machine with Servo Drive redefines precision and efficiency in the printing industry. With its servo-driven components, customizable rotation, and eco-friendly features, this machine offers a comprehensive solution for businesses seeking advanced printing capabilities with a focus on environmental responsibility.

Machine videos

DSTAR machine

DSTAR machine

WeChat

Scan the QR Code with wechat