plastic toys pad printing machine

Pad printing machine(also called tampo printing machine) is a printing process that can transfer a 2D image onto a 3D object. This is accomplished using an indirect offset (gravure) printing process that involves an image being transferred from the cliché via a silicone pad onto a substrate.

DX-MINI2SB-90 pad printer

- DX is short name of our company

- MINI is one of the pad printer series(MINI,P,S,M,L)

- 2 mean 2 color

- S mean sliding shuttle

- B mean Machine with Base

- 90 means machine with ¢90mm ink cup

Technical parameters

Product:toys pad printing machine

Model:DX-MINI2SB-90 (sealed ink cup system)

Standard printing plate size:0.3*100*225mm

Ink cup diameter:¢90mm

Printing color:2 color

H.S code:84431980

Printing speed:1600 times/hr

Air pressure:5-7 bar

N.W:75 kgs

Machine dimension:L56*W45*H120 cm

Packing:wooden case

Pad printer consumables

- Pad printing plate

- Silicone pad

- Pad printing ink and ink solvent

- Work piece fixture

- Ink blade(for open ink well system)

- Sealed ink cup (for ink cup system)

Pad printing samples

Pad printing samples

- Stationery industry printing

- Textile printing

- Medical supplies printing

- Hardware printing

- Electronic printing

- Toys printing

- Packing printing

- Glass products printing

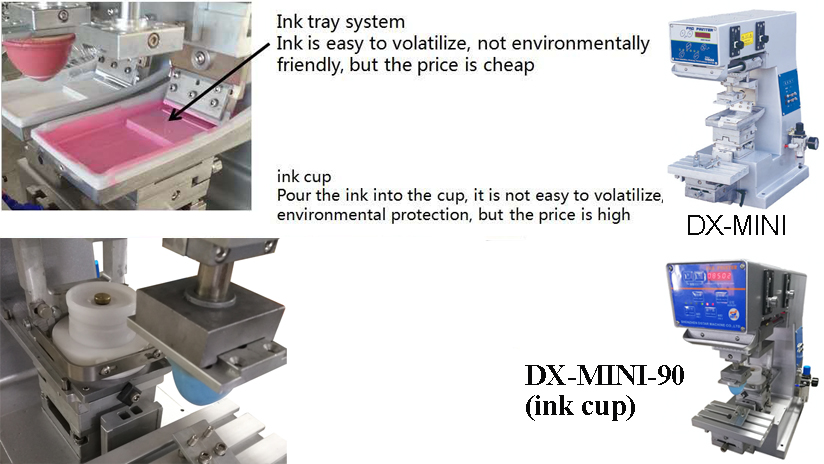

Difference between open ink well and sealed ink cup

Open ink well systems, the older method of pad printing, used an ink trough for the ink supply, which was located behind the printing plate. A flood bar pushed a pool of ink over the plate, and a doctor blade removes the ink from the plate surface, leaving ink on the etched artwork area ready for the pad to pick up.

Sealed ink cup systems employ a sealed container which acts as the ink supply, flood bar and doctor blade all at the same time. A ceramic ring or tungsten ring with a highly polished working edge provides the seal against the printing plate.

DSTAR machine

DSTAR machine

WeChat

Scan the QR Code with wechat