2 color pad printing machine

Product:2 color pad printing machine with pad cleaning

Model:DX-SP2S-90

Printing color:2 color

Pad printing plate size:100*220mm

Ink cup size:90mm

F/B Stroke:200mm

U/D Stroke:75mm

Central stroke:150mm

Printing speed:1200 cycles/hr

Work table Z adjustable height:200mm

Power:AC220V/1Phase/850W

Air supply:0.5-0.7Mpa

Size::L950*W650*H1350mm

N.W:200KGS

- Silicone pad forward and backward movement with servo motor drive

- Worktable shuttle is driven with servo motor,the horizontal movment stroke can be user defined on HMI.

- Automatic silicone pad cleaning,the cleaning frequency can be user defined on HMI according printing requirements.

- Panasonic PLC system and 7” HMI touch screen

- Silicone pad UP/DOWN printing stroke can be adjustable

- Worktable can be X.Y.Z.R adjustable

- Sealed ink cup to be eco friendly and save ink.

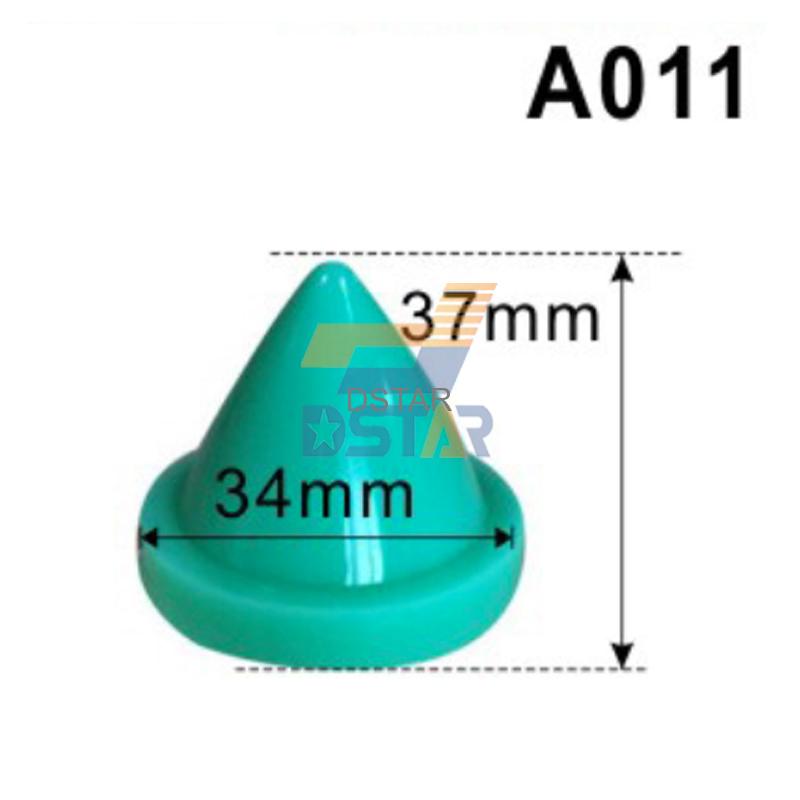

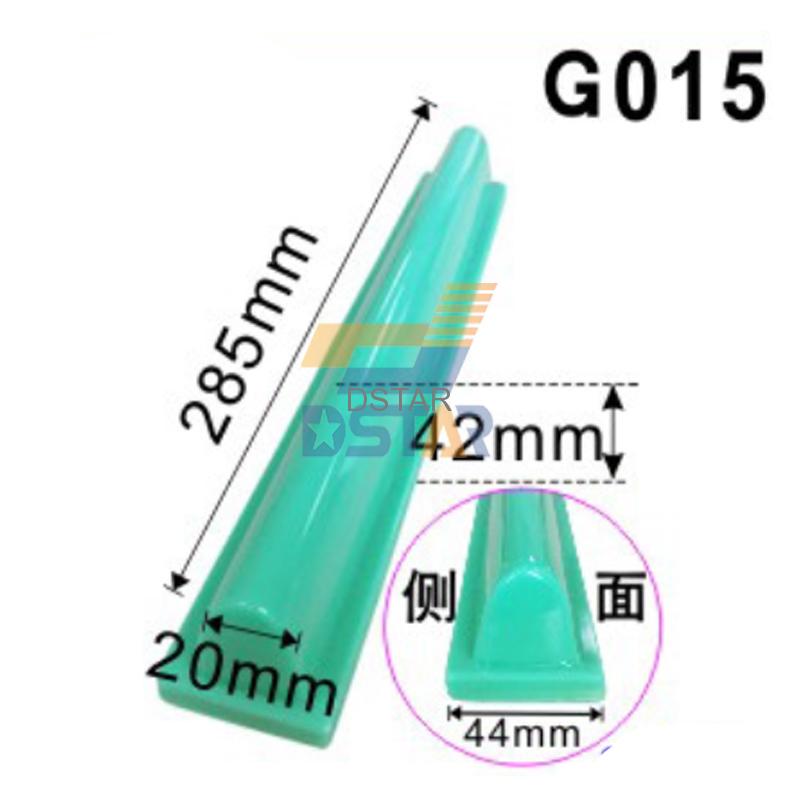

- Silicone pad

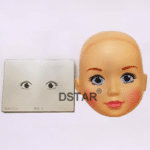

- Pad printing plate

- Printing ink and ink solvent

- Fixture

- Ink cup or ink blade

Pad printing is a printing process that can transfer a two-dimensional image onto a 3D object. It’s commonly used for printing on irregularly shaped surfaces and materials like plastics, metals, ceramics, and glass.

2 color pad printing machine typically refers to a machine capable of printing using two different colors in a single pass. This is achieved by having two separate ink cups and pads on the machine. The process involves transferring ink from the engraved plate (cliché) to a silicone pad, which then presses against the object to be printed.

How does pad printing machine work?

Ink Cup and Cliché Setup:

- The machine has an ink cup containing a pool of ink, and a cliché, which is a metal or polymer plate engraved with the desired image or pattern.

- The cliché is coated with ink, and excess ink is removed by a doctor blade, leaving ink only in the engraved areas.

Silicone Pad:

- The heart of the tampo printing process is the silicone pad, often made of silicone rubber. This pad picks up the ink from the cliché.

Printing Process:

- The transfer pad moves from its initial position to the ink cup, picking up the ink as it compresses against the cliché.

- The pad then moves to the object to be printed, and the ink is transferred from the pad to the object. The pad’s flexibility allows it to conform to the shape of the object, making it suitable for irregular surfaces.

DSTAR machine

DSTAR machine

WeChat

Scan the QR Code with wechat