Pad printing technical problem and solution

Possible causes and solutions

1.Silicone pad is too soft

use a slightly harder Silicone pad.Improper selection of the shape of the Silicone pad. Try a different shape of the Silicone pad.

2.Pad printing plate

Inaccurate corrosion of the pad printing plate.Remake a pad printing plate.

Pad printing plate has too deep corrosion depth.Re-etch a moderately deep pad printing plate

Inappropriate selection of the type of pad printing plate material.Select the appropriate type of pad printing plate (e.g. replace the polyester version with a steel version)

Improper screen selection, try another screen

3.Printing ink

The ink is too viscous, add some thinner to the ink

The ink is too thin, reduce the amount of thinner in the ink

Ink drying speed is too slow, change to a thinner with faster drying speed

4.printing materials

The surface of the object is not clean. Clean the surface of the printed object in advance.

Surface is hard and granular. If possible, change to another material. Or try a harder pad printing head

The surface has a high degree of unevenness. The special-shaped pad printing head and pad printing head base device are adopted.

is printed on the edge of the object, the fixture must be able to prevent the pad printing rubber head from sliding

5. Other possible causes

The workpiece fixture is not stable enough. Change to a new workpiece fixture

High-speed printing leads to deformation of the silicone pad, which reduces the printing speed. If necessary, pause for a while before the ink is ready to transfer, the purpose is to restore the deformation of the silicone pad

Silicone pad

Silicone pad

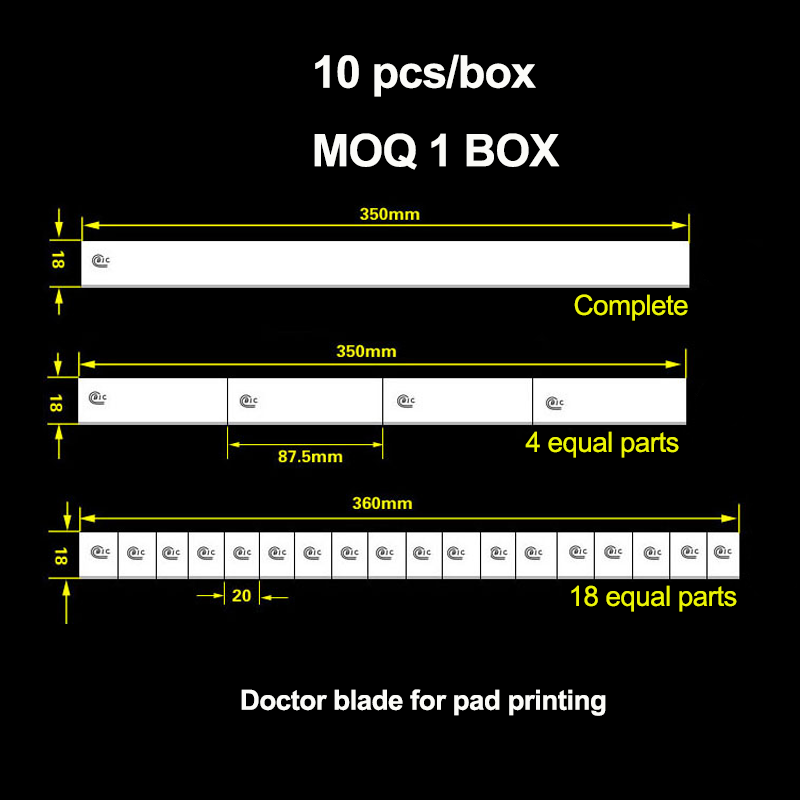

Ink scrap blade

DSTAR machine

DSTAR machine

WeChat

Scan the QR Code with wechat