pad printing and screen printing in cosmetic packaging industry

1. Pad Printing

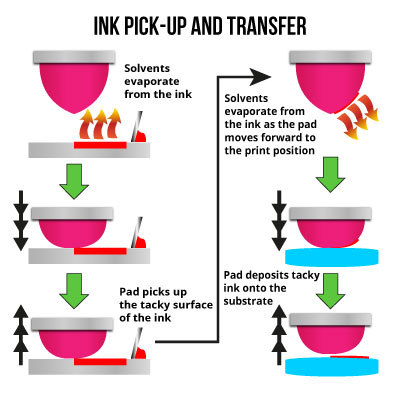

Principle: Uses a silicone pad to transfer designs from etched metal or resin plates onto curved or irregular surfaces.

Applications:

- Irregular surfaces: Lipstick tubes, compact case lids, uniquely shaped bottles, or textured packaging components.

- Fine details: Brand logos, small text, gradient colors (e.g., shade labels on lipstick tubes).

- Small-batch customization: Ideal for limited editions or personalized designs.

Advantages:

- Versatile for materials like plastic, glass, and metal.

- Excellent for curved or uneven surfaces.

- Cost-effective for low-volume production.

Limitations:

- Low efficiency for large-area printing; colors may lack vibrancy compared to screen printing.

- Multi-color designs require precise alignment.

Examples: Embossed patterns on high-end eyeshadow palettes, intricate logo printing on perfume caps.

2. Screen Printing

Principle: Ink is forced through a mesh stencil onto flat or slightly curved surfaces.

Applications:

- Flat/mildly curved surfaces: Cosmetic boxes, large color blocks, gradient designs, or matte finishes on bottles.

- High opacity needs: Light text on dark backgrounds (e.g., white logos on black bottles).

- Special effects: Pearlescent, fluorescent, or thermochromic inks (e.g., glow-in-the-dark packaging).

Advantages:

- Vibrant colors and strong coverage for bold designs.

- Thick ink layers create tactile effects (e.g., UV-raised text).

- Cost-efficient for mass production.

Limitations:

- Poor adaptability to highly curved or complex shapes.

- Multi-color designs require multiple stencils, reducing precision and speed.

Examples: Gradient-colored skincare bottles, matte-textured gift boxes.

3. Hot Stamping

Principle: Heat and pressure transfer metallic foil (gold, silver, holographic) onto surfaces using metal dies.

Applications:

- Luxury accents: Brand logos, decorative borders, or metallic highlights.

- Anti-counterfeiting: Holographic or laser foils for premium or limited editions.

- Material versatility: Works on paper, plastic, leather, etc.

Advantages:

- Instantly elevates perceived value with lasting metallic finishes.

- Combines with embossing for 3D effects.

- Solvent-free and environmentally friendly.

Limitations:

- High foil costs; designs must avoid overlapping printed areas.

- Complex patterns require high-precision dies, raising costs for small batches.

Examples: Gold-stamped logos on perfume boxes, 3D foil patterns on luxury cream jar lids.

Key Considerations for Process Selection

- Brand Positioning:

- Luxury brands often combine hot stamping + pad printing (e.g., foil logos + detailed pad-printed textures).

- Mass-market brands prioritize screen printing with cost-effective special inks.

- Design Complexity:

- Multi-color gradients favor screen printing.

- Curved/irregular shapes require pad printing.

- Metallic or 3D effects demand hot stamping.

- Production Scale:

- Pad printing suits small batches.

- Screen printing or automated hot stamping excels in mass production.

- Sustainability & Compliance:

- Foils must meet REACH/FDA safety standards.

- Water-based screen inks reduce VOC emissions.

Trends & Innovations

- Hybrid techniques: Screen-printed bases + localized foil stamping, or pad-printed designs + UV spot varnish.

- Eco-friendly foils: Biodegradable or recycled foils to minimize environmental impact.

- Digital integration: Combining digital printing’s flexibility with traditional textures for customization.

Summary

In cosmetic packaging, pad printing, screen printing, and hot stamping each offer unique value. Brands must strategically select or blend these processes based on product positioning, design goals, and budgets to balance functionality and aesthetics. By leveraging these techniques, packaging becomes a powerful tool to convey brand identity and enhance user experience in a competitive market.

Welcome contact DSTAR Machine if you need further refinements!

DSTAR machine

DSTAR machine

WeChat

Scan the QR Code with wechat