silicone pad for pad printing glass lens and temple

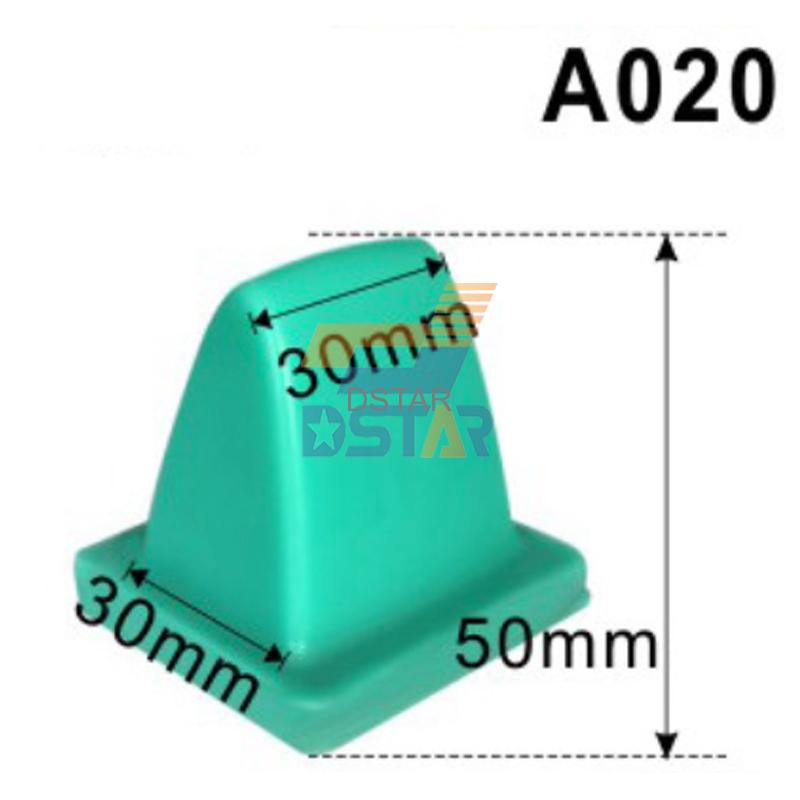

The shape of the silicone pad must be able to print to the specified position, and secondly, it must be deformed a bit. Since the printing area of the frame is very large, the pad printing rubber head should be very sharp. Through the test, a rubber head with a cross-sectional area of 38 mm is more suitable.

The hardness of the pad printing rubber head is another indicator that should be considered when choosing. The softer rubber head has a wider adaptability, but the printing image and text are deformed. Especially for printed products as small as eyeglass frames, the graphics and text are very small, and the large deformation of the graphics and text can easily cause the adhesion between the graphics and text lines and become blurred. Therefore, it is better to choose a harder plastic head. Our test The result is that a plastic head with a Shore hardness of 30 degrees can achieve good printing quality.

The rubber head selected for the printing of the nose pad part should be selected with a smaller cross-sectional area considering the limitation of the position. Our test result is that the rubber head with the cross-sectional area below 15mm is more suitable, and the hardness should also be 30 degrees (parameters will (Different due to different test tools)

Silicone pad

Tampo rubber

Silicone rubber

DSTAR machine

DSTAR machine

WeChat

Scan the QR Code with wechat