Pad printing machines for branding

Introduction: In today’s competitive manufacturing landscape, achieving precise and impactful branding on various surfaces is paramount. This has propelled pad printing machines to the forefront as a versatile and efficient solution for customization. In this comprehensive guide, we will explore the intricate details of pad printing machines, shedding light on their features, benefits, and how they can optimize your printing processes to elevate your brand’s visibility and recognition.

Understanding Pad Printing Machines

1.1 Defining Pad Printing: An Overview of the Process

1.2 The Mechanics Behind Pad Printer: Precision at Work

1.3 Exploring Different Types of Pad Printer Machine: From Manual to Automated Systems

Key Features and Components

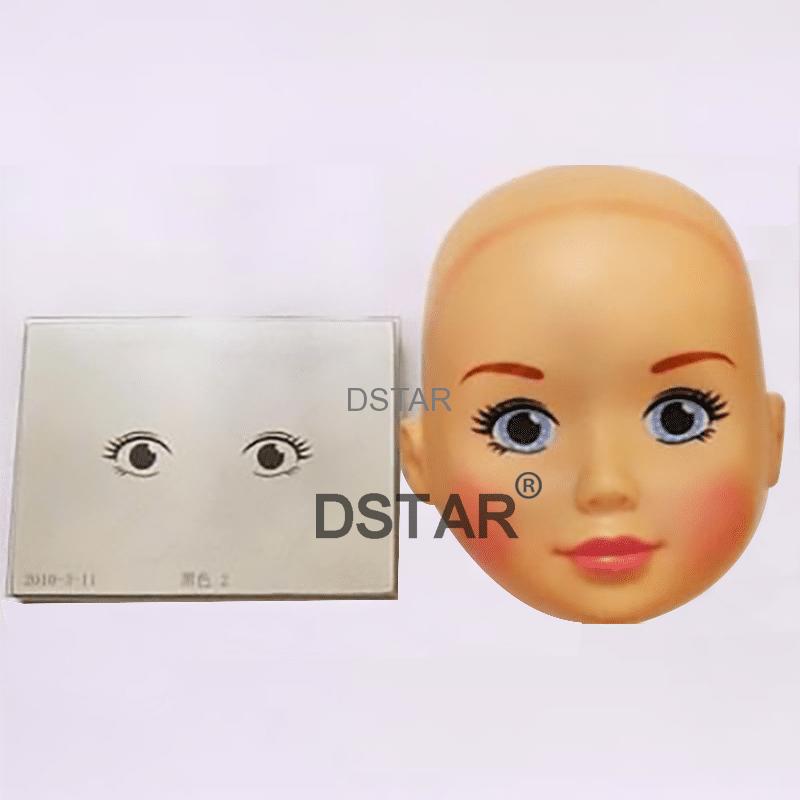

2.1 Pad Printing Plates: The Epitome of Precision and Detail

2.2 Ink Cups: The Crucial Element for Consistent and Clean Transfers

2.3 Pad Materials: Striking the Perfect Balance of Softness and Durability

2.4 Machine Controls and Programming: Enhancing Flexibility, Accuracy, and Efficiency

Benefits of Pad Printing Machines

3.1 Versatility Unleashed: Conquering Diverse Substrates with Ease

3.2 Exquisite Printing Quality: Achieving Sharpness, Vibrancy, and Fine Detail

3.3 Cost-Effectiveness Redefined: Maximizing Efficiency and Productivity

3.4 Rapid Set-up and Changeover: Adapting to Demanding Production Schedules

Applications and Industries

4.1 Automotive and Aerospace: Personalizing Parts and Components

4.2 Electronics and Appliances: Elevating Branding with Unmatched Precision

4.3 Promotional Products: Adding Value and Captivating Audiences

4.4 Medical and Pharmaceutical: Meeting Stringent Compliance Standards

Selecting the Perfect Pad Printing Machine

5.1 Critical Factors for Machine Selection: Capacity, Speed, and Versatility

5.2 Evaluating Production Requirements: Output Volume and Printing Parameters

5.3 Maintenance and Technical Support: Ensuring Smooth Operations

Advanced Techniques for Optimizing Pad Printing Processes

6.1 Design Considerations for Pad Printing: Overcoming Challenges and Maximizing Impact

6.2 Artwork and Image Preparation: Achieving Impeccable Clarity and Detail

6.3 Troubleshooting Common Issues: Enhancing Efficiency and Minimizing Downtime

6.4 Implementing Quality Control Measures: Ensuring Consistency and Perfection

Conclusion: Pad printer machine have revolutionized precision printing, empowering businesses to achieve remarkable branding and customization results. By harnessing the capabilities of pad printer machines and employing advanced techniques, you can unlock new dimensions of brand recognition and product appeal. Embrace the power of pad printing machine to transform your printing processes and propel your brand to new heights of success.

Keywords: pad printing machine, pad printing, printing plates, ink cups, pad materials, versatility, high-quality printing, cost-effectiveness, rapid set-up, applications, industries, machine selection, optimization, customization, branding, precision printing.

DSTAR machine

DSTAR machine

WeChat

Scan the QR Code with wechat