pad printing ink adhesion problem

The adhesion of the ink does not meet the requirements

This failure is very common in pad printing, because you do not know the ink formula, or the type of ink selected is incorrect.

Possible causes and solutions

1.Silicone pad

There is too much silicone rubber on the surface of the pad printing head. Before using the new pad printing head, clean the new pad printing head with an alcohol solvent.

2.pad printing artwork depth

The artwork is etched too much depth, remake the pad printing plate with a moderate depth.

3.ink

Ink type selection is not appropriate, choose appropriate ink according to the specific conditions of the printing material.

Double-part ink is used. If double-part ink is selected, a pad printing rubber head with greater hardness should be used for printing.

The proportion of ink and hardener is incorrect. Weigh the quantity of ink and hardener according to the ratio, and then remix the ink.

4.printing materials

The surface is not clean. Use alcohol solvent to clean the surface of the object before printing.

5. Other reasons

(1) Insufficient pre-processing work or no pre-processing Check the pre-processing procedures. If possible, repeat the pre-processing work.

(2) The fixation time requirement is not met. Before the pre-tested ink bond firmness, let the printed matter be fully dried and fixed.

(3) Insufficient post-processing work. Heat pipes are used, and flame drying devices are sometimes needed.

Printing ink

Pad printing plate

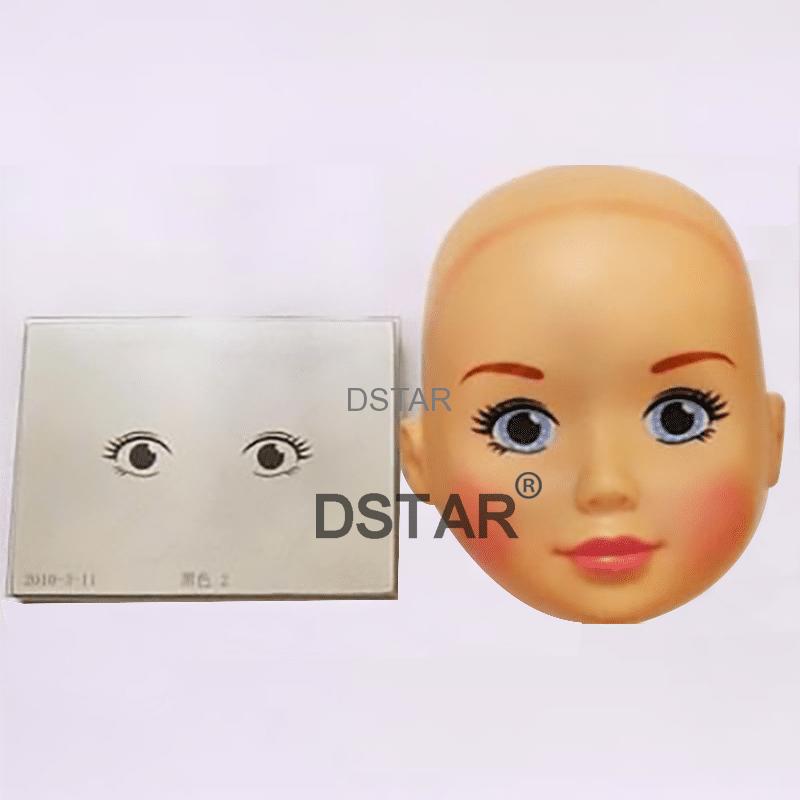

Silicone pad

DSTAR machine

DSTAR machine

WeChat

Scan the QR Code with wechat