non woven shopping bag printing machine

A 1-color screen printing machine designed for non-woven shopping bags and paper bags with manual feeding, automatic printing, and automatic unloading is a great solution for efficient, high-quality printing of custom designs on these types of bags. This type of machine is commonly used in medium to high-volume production, offering a balance of manual input and automatic operations, which helps improve production speed while maintaining flexibility for custom or smaller runs.

Key Features of the 1-Color Screen Printing Machine

Manual Feeding:

- Operators manually place the bags on the belt.

- This provides flexibility in handling different sizes and types of bags.

- Ideal for small to medium batches or when high customization is needed.

- Vacuum suck the product during printing.

Automatic Printing:

- The machine is equipped with an automatic screen printing mechanism that accurately transfers the design onto the bags.

- The screen mesh holds the design, and ink is pushed through the mesh using a squeegee, transferring the image onto the bag.

- Automatic printing ensures consistent quality and faster print speeds compared to fully manual operations.

Automatic Unloading:

- After printing, the machine automatically removes the printed bags from the printing area.

- This increases efficiency and helps keep the production line moving without the need for manual intervention in unloading.

- The bags are often collected onto a conveyor system or stacked for easy access and packaging.

1-Color Printing:

- The machine is designed to print a single color in one pass. This is ideal for simple logos, text, or designs.

- Typically used for one-color branding, but you can always re-run the bags with additional colors if needed (though this will require additional setup).

Key Components of the Machine:

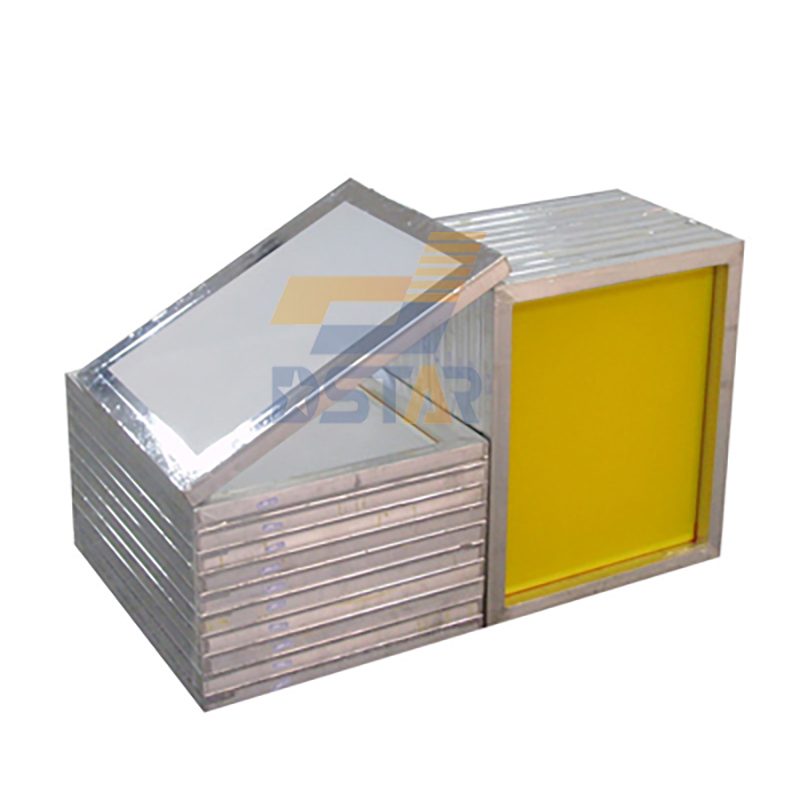

- Printing Frame and Screen:

- The screen is where your design is transferred. It’s made of mesh material and is stretched over a frame.

- The frame holds the screen in place during printing and is often adjustable to accommodate different bag sizes.

- Squeegee and Flood Bar:

- The squeegee is a rubber blade that pushes ink through the screen onto the bag, ensuring the design is printed clearly and evenly.

- The flood bar helps distribute ink evenly across the screen before the squeegee moves to print.

- Ink Tray/Ink Cup:

- The ink tray holds the printing ink, which is used to print the design onto the surface of the bags.

- Some machines have automatic ink delivery systems to ensure consistent flow of ink during the printing process.

- Conveyor or Unloading System:

- After printing, the bags are either placed on a conveyor belt for further processing or automatically ejected into a stacker or unloading station.

- The automatic unloading feature helps reduce downtime and labor requirements.

- Control Panel:

- The user interface that allows the operator to set printing parameters, such as printing speed, pressure, and timing.

- It also helps in adjusting settings for bag size, screen tension, and ink type.

- Bag Holder/Feeding Platform:

- A platform or fixture holds the bag in place while it is being printed. For non-woven and paper bags, these fixtures can often be adjusted to accommodate different sizes and bag types.

Advantages of a 1-Color Screen Printing Machine for Bags:

- Speed and Efficiency:

- Automated features such as printing and unloading significantly increase throughput compared to fully manual systems, making it suitable for medium-scale production runs.

- Cost-Effective:

- A single-color machine is generally more affordable than multi-color screen printing machines, and it is highly effective for simple designs (e.g., logos, text).

- High-Quality Prints:

- Screen printing offers high opacity, vibrant colors, and durability, ensuring that the prints on non-woven or paper bags last a long time, even under rough handling.

- Customizability:

- The machine can handle various bag sizes and materials, making it suitable for different types of non-woven or paper bags, including eco-friendly and promotional items.

- Easy Operation:

- The semi-automatic design (manual feeding with automatic printing and unloading) allows operators to maintain control while benefiting from increased efficiency.

Applications:

- Retail and Promotional Bags: Printing company logos, product images, or marketing messages on non-woven shopping bags and paper bags.

- Event and Packaging Bags: Custom printing for corporate events, trade shows, and retail packaging.

- Eco-Friendly Branding: Non-woven bags, often used as eco-friendly alternatives to plastic bags, can be printed with sustainable messages or logos.

Considerations When Choosing a Machine:

- Bag Size and Material:

- Make sure the machine is capable of handling the sizes and thicknesses of non-woven and paper bags you plan to print. Adjustability in the print bed size is essential for versatility.

- Ink Type:

- The machine should be compatible with inks designed for non-woven materials and paper. Water-based or eco-friendly inks are often used for environmental sustainability and safety, especially with paper and fabric-like materials.

- Printing Speed:

- Consider the speed of the printing cycle. Higher printing speeds are important for meeting deadlines or large orders, but make sure that print quality is not sacrificed for speed.

- Maintenance and Support:

- Check the ease of maintenance and whether spare parts or technical support are readily available. Good service and maintenance can help ensure long machine life.

- Automation Level:

- Some machines may have more advanced automation (e.g., automatic bag feeding) which can further reduce manual labor but may also increase cost. Balance automation needs with your budget.

Conclusion:

A 1-color screen printing machine for non-woven shopping bags and paper bags, with manual feeding, automatic printing, and automatic unloading, provides an efficient, cost-effective solution for businesses looking to print simple designs on a variety of bags. The semi-automatic nature of the machine improves production speed while still offering flexibility for custom orders, making it a great choice for companies with mid-range production needs.

DSTAR machine

DSTAR machine

WeChat

Scan the QR Code with wechat