hot stamping and screen printing for wine packing

Introduction

The application of hot stamping and silk screen printing technology in the wine packaging industry is becoming increasingly popular. These two processes are used for various wine packaging applications, ranging from logos to decorative elements. Hot stamping and silk screen printing are relatively cost-effective processes that provide a wide range of options for wine packaging. This paper will discuss the advantages and disadvantages of these two processes in detail, and how they are used in the wine packaging industry.

Hot stamping

Hot stamping is a process that uses heat and pressure to transfer a design, such as a logo or decorative element, onto the surface of a product. The process begins by pressing a heated die onto the surface of the product. The heat and pressure transfer the design onto the product. Hot stamping is often used for logos, as it provides a high-quality, professional finish.

Advantages

One of the advantages of hot stamping is that it is a relatively inexpensive process. It is also a fast process, which makes it ideal for high-volume production. Additionally, hot stamping is a versatile process, as it can be used on a wide variety of materials, including plastic, leather, and paper.

Disadvantages

The main disadvantage of hot stamping is that it is not suitable for small designs. Additionally, the process is limited in terms of the number of colors that can be used, as only one color can be used at a time.

Screen printing

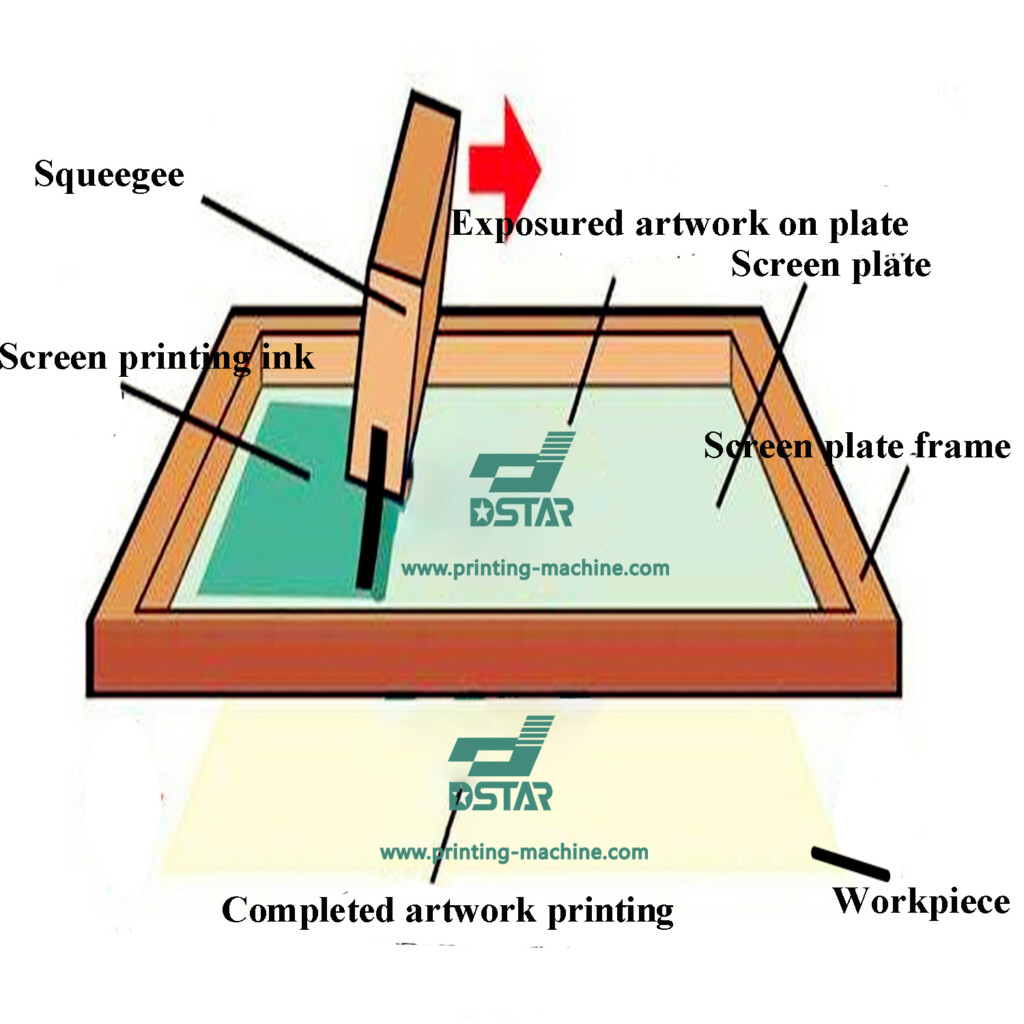

Silk screen printing is a process that uses a mesh screen to transfer a design onto a product. The process begins with the creation of a stencil, which is then adhered to a mesh screen. Ink is then forced through the mesh screen onto the product, transferring the design onto the product.

Advantages

One of the advantages of silk screen printing is that it can be used to transfer complex designs onto products. Additionally, the process is relatively fast and cost-effective. Additionally, silk screen printing can be used to apply a wide range of colors and effects.

Disadvantages

The main disadvantage of silk screen printing is that it is a labor-intensive process. Additionally, the process is limited in terms of the number of colors that can be used, as only one color can be used at a time. Application in Wine Packaging

Hot stamping and screen printing are both widely used in the wine packaging industry. Hot stamping is often used to apply logos to wine bottles, while silk screen printing is used to apply decorative elements and colors. Additionally, both processes can be used to apply shrink sleeves to wine bottles. Shrink sleeves are used to provide a tight, secure fit and are often used to enhance the appearance of wine bottles.

Conclusion

In conclusion, hot stamping and silk screen printing are both widely used processes in the wine packaging industry. Hot stamping is a relatively inexpensive and fast process, which is ideal for high-volume production. Silk screen printing is a more labor-intensive process, but it is well-suited for complex designs and a wide range of colors. Both processes are used to create attractive and professional wine packaging.

DSTAR machine

DSTAR machine

WeChat

Scan the QR Code with wechat