To know the Film application for different printing machine

Application(film for pad printing) :

- Film is used to create the steel or plastic plates where the graphic areas are etched through exposure and corrosion to form recessed areas. The pad then transfers the pattern to the substrate.

- Commonly used for printing on irregular surfaces, such as toys, electronic products, and household items.

Features:

- Negative Film: Negative film (black areas represent the graphic) is used to make the printing plate. Photosensitive materials harden through exposure to light, forming the graphic areas.

- High edge clarity is required, especially for fine patterns or small fonts

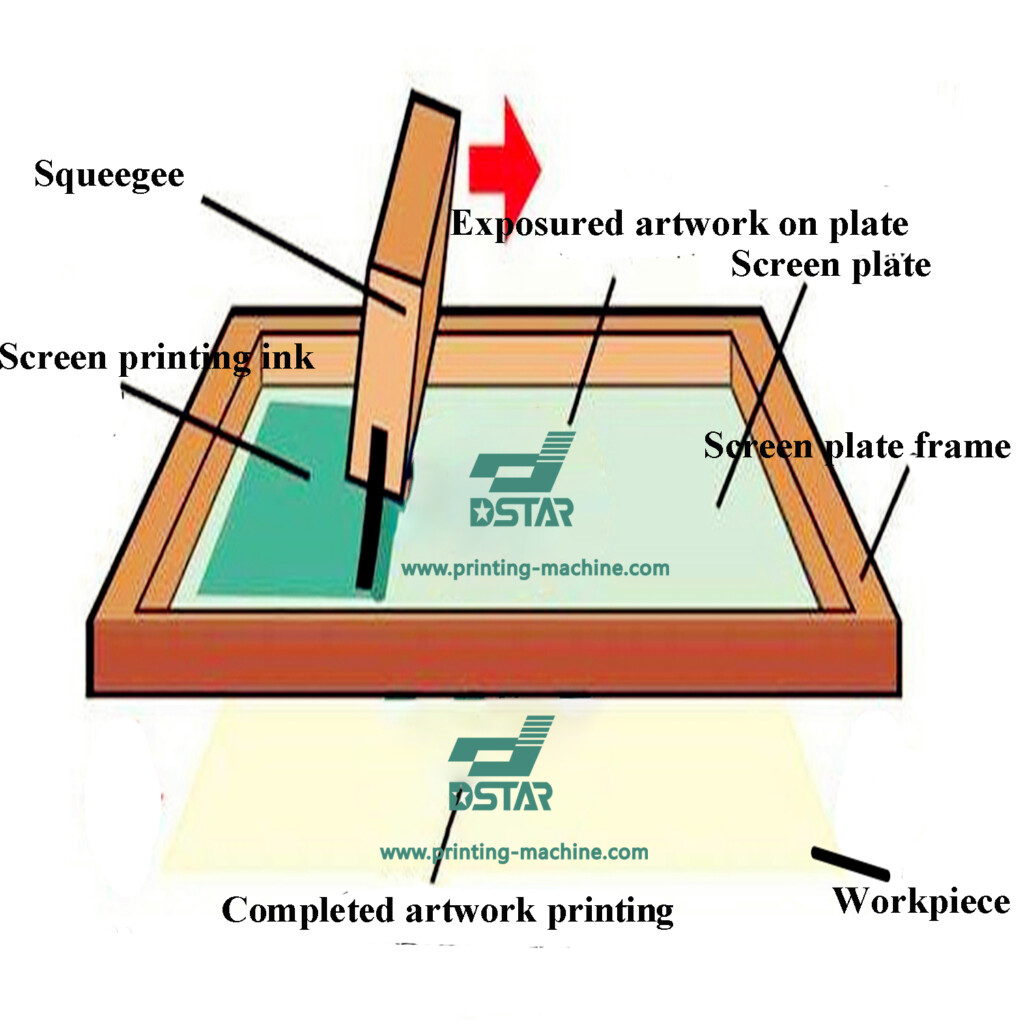

Application:

- Film is used to create the screen plate by transferring the graphic areas onto the screen through exposure and development. Unexposed areas are washed away to form open areas for ink transfer.

- Widely used in signage, textiles, and printed circuit boards.

Features:

- Positive Film: Positive film (transparent areas represent the graphic) is used. After exposure, the photosensitive emulsion hardens, and unexposed areas are washed away to form the graphic areas.

- High opacity is required for the film to completely block light, ensuring sharp and clear graphic areas.

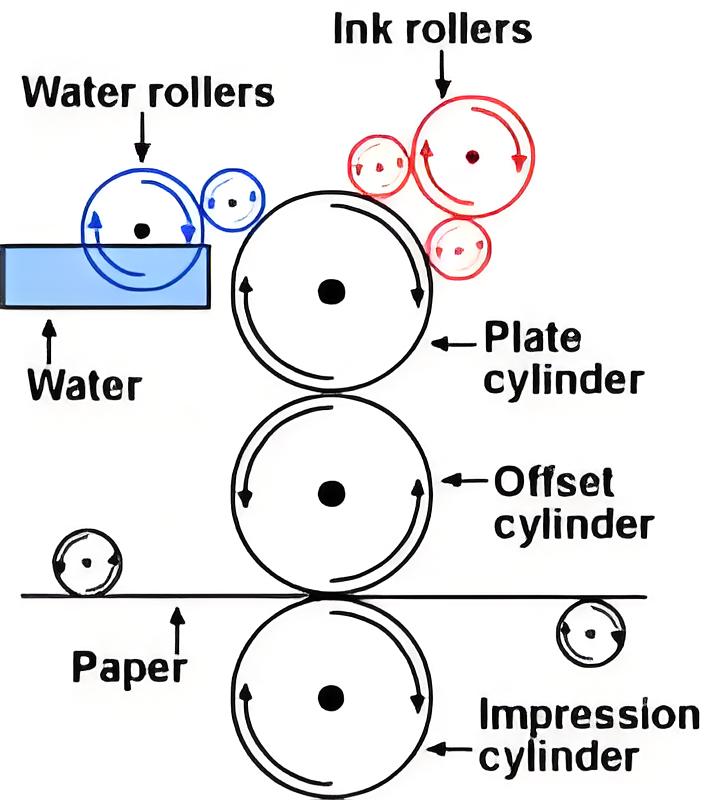

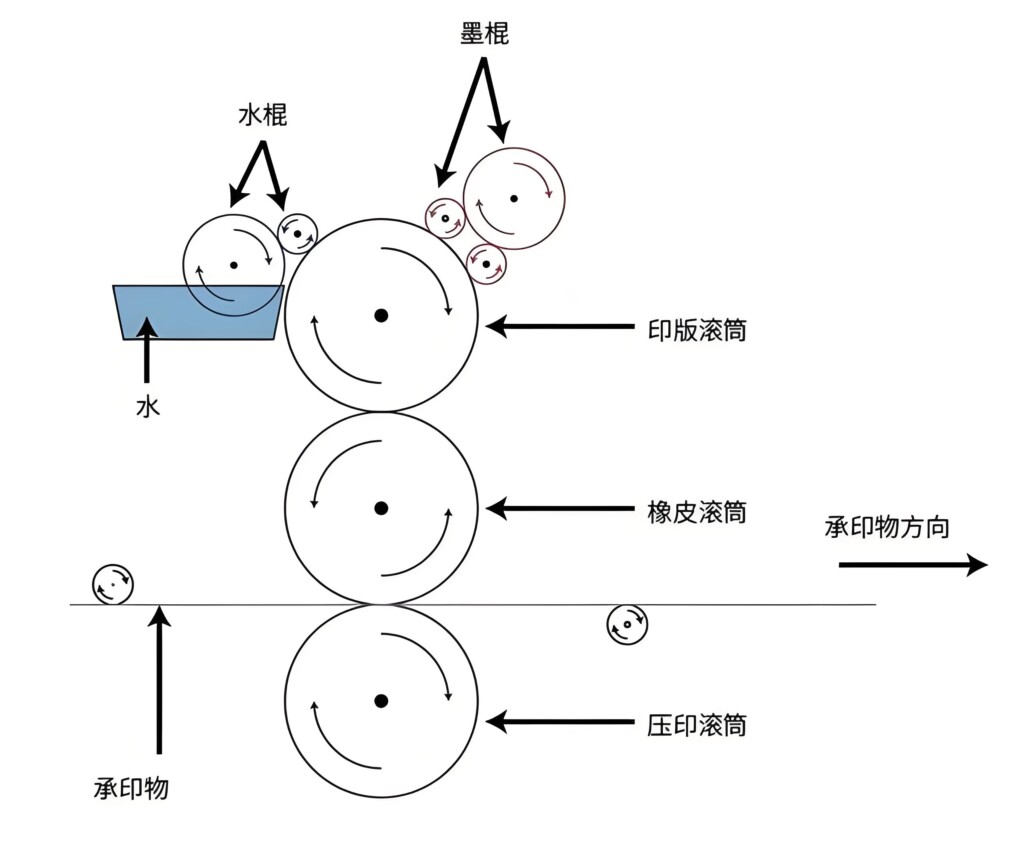

Application:

- Film is used to create PS plates (photosensitive plates) by transferring the graphic areas through exposure and development, forming oleophilic (ink-receptive) regions.

- Commonly used for books, magazines, brochures, and other large-scale printing.

Features:

- Negative Film: Negative film is used to create PS plates, where black areas represent the graphic regions.

- The film requires high precision and contrast to ensure clear dot patterns and accurate registration.

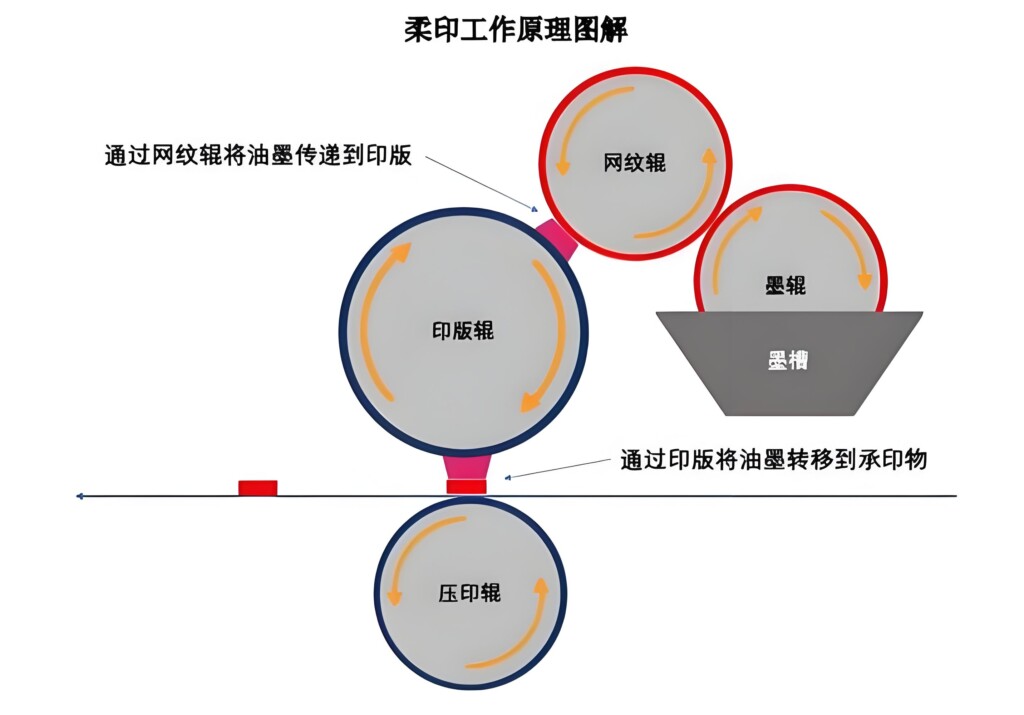

Application:

- Film is used to create flexographic plates, where the graphic areas are raised through exposure and washing.

- Widely used for packaging printing, such as cartons, labels, and plastic bags.

Features:

- Positive Film: Positive film is used, with transparent areas representing the graphic regions. After exposure, the hardened areas form raised graphic regions.

- The film requires high resolution and edge clarity to match the characteristics of flexographic printing.

Application:

- Film is used to create letterpress plates by transferring the graphic areas through exposure and development.

- Commonly used for labels, tickets, and specialty packaging.

Features:

- Positive Film: Positive film is used, where transparent areas represent the graphic regions.

- The film requires high opacity and sharp edges to ensure the quality of the raised graphic areas on the plate.

Application:

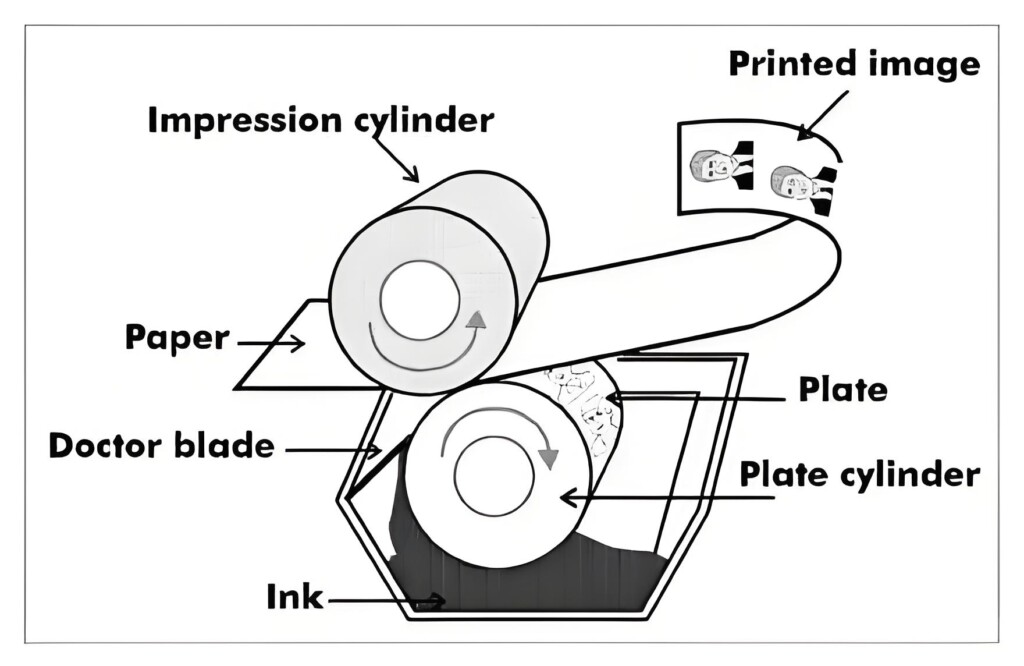

- Film is used to create gravure plates, where graphic areas are engraved as recesses through electroplating or laser engraving. The depth of the recesses determines the ink volume.

- Widely used for high-quality packaging, currency, and magazine printing.

Features:

- Negative Film: Negative film is used, where black areas represent the recessed regions.

- The film requires extremely high resolution and continuous density to ensure precise depth and quality of the engraved recesses.

Different film for printing machine Between Negative and Positive Film

| Feature | Negative Film | Positive Film |

|---|---|---|

| Graphic Areas | Black areas represent the graphic; | Transparent areas represent the graphic; |

| Transparent areas are non-graphic. | Black areas are non-graphic. | |

| Usage | Commonly used in pad printing, offset | Commonly used in screen printing, flexographic, |

| printing, and gravure printing. | and letterpress printing. | |

| Light Blocking | Black areas block light to form graphic areas. | Transparent areas allow light to form graphic areas. |

| Precision | High contrast and fine dot patterns are required. | High opacity and sharp edges are essential. |

DSTAR machine

DSTAR machine

WeChat

Scan the QR Code with wechat