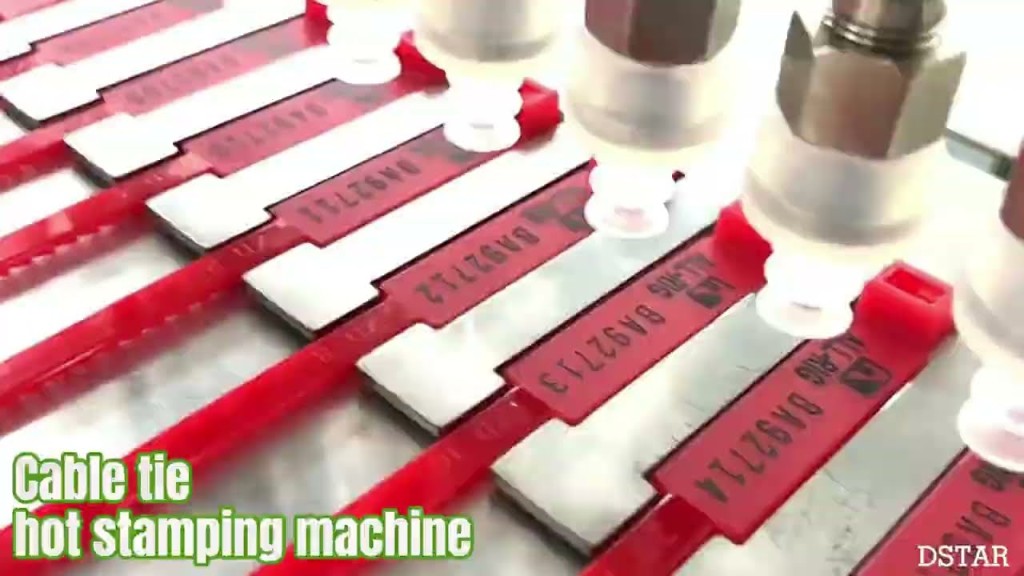

Cable tie hot stamping machine

In the fast-paced world of cable management, precision and durability are paramount. Shenzhen DSTAR Machine Co., Ltd. steps into this arena with its cutting-edge Cable Tie Hot Stamping Machine, a technological marvel designed to enhance the functionality and aesthetic appeal of cable ties across various industries.

Manufacturer Overview

Shenzhen DSTAR Machine Co., Ltd. has earned a reputation as an industry leader in the manufacturing of specialized printing machinery. With a commitment to innovation and customer satisfaction, the company has introduced a Cable Tie Hot Stamping Machine that addresses the unique needs of cable management with a focus on efficiency and visual impact.

Machine Features:

- Hot Stamping Precision: The Cable Tie Foil Stamping Machine employs advanced hot stamping technology to transfer foil onto cable ties with precision. This ensures that not only the branding and identification information but also intricate designs and logos are flawlessly imprinted on each cable tie.

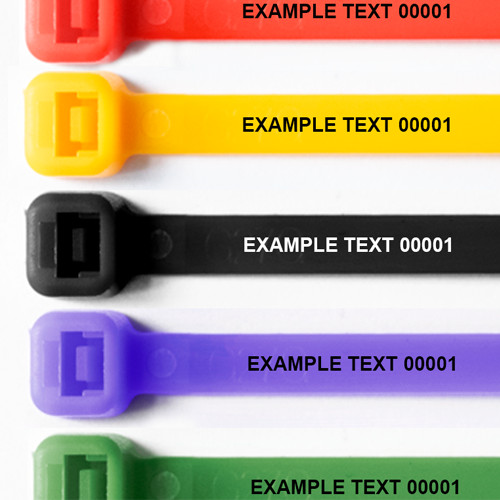

- Variety of Foil Options: To cater to diverse industry requirements, the machine supports the use of various foils. This includes metallic foils for a professional and sleek appearance, as well as colored foils to aid in color-coding and quick identification. The versatility in foil options adds a layer of customization to cable tie applications.

- High-Speed Production: Recognizing the demand for efficiency in cable tie manufacturing, Shenzhen DSTAR’s machine boasts high-speed production capabilities. This ensures that large quantities of cable ties can be stamped with precision and consistency, meeting the fast-paced needs of industries such as electronics, automotive, and logistics.

- User-Friendly Operation: The machine is equipped with a user-friendly interface, allowing operators to easily set up and monitor the hot stamping process. This feature minimizes the learning curve, making the machine accessible to both experienced professionals and those new to the technology.

- Customization for Different Tie Sizes: Acknowledging the variety in cable tie sizes, the Cable Tie Foil Stamping Machine is designed to accommodate different dimensions. This adaptability ensures that the hot stamping process remains consistent across various cable tie sizes, maintaining quality standards throughout production.

Advantages of Hot Stamping on Cable Ties:

- Durability and Longevity: Hot stamping creates durable and long-lasting imprints on cable ties. The stamped information and designs remain legible and intact even in challenging environments, ensuring reliable identification throughout the lifespan of the cable ties.

- Professional Branding: Hot stamping elevates the branding of cable ties, providing a professional and polished appearance. This is crucial for companies looking to enhance brand visibility and convey a sense of quality and reliability to end-users.

- Resistance to Wear and Tear: The stamped information on cable ties is resistant to wear and tear, ensuring that essential details such as serial numbers, specifications, or branding remain visible and intact despite the rigors of handling and usage.

Conclusion: Shenzhen DSTAR Machine Co., Ltd.’s Cable Tie Foil Stamping Machine emerges as a game-changer in the cable management industry. By combining the precision of hot stamping technology with user-friendly operation and adaptability, the machine sets new standards for efficiency and aesthetics in the production of cable ties. As industries continue to seek innovative solutions for cable identification and branding, this machine stands at the forefront, securing excellence in cable tie manufacturing.

DSTAR machine

DSTAR machine

WeChat

Scan the QR Code with wechat