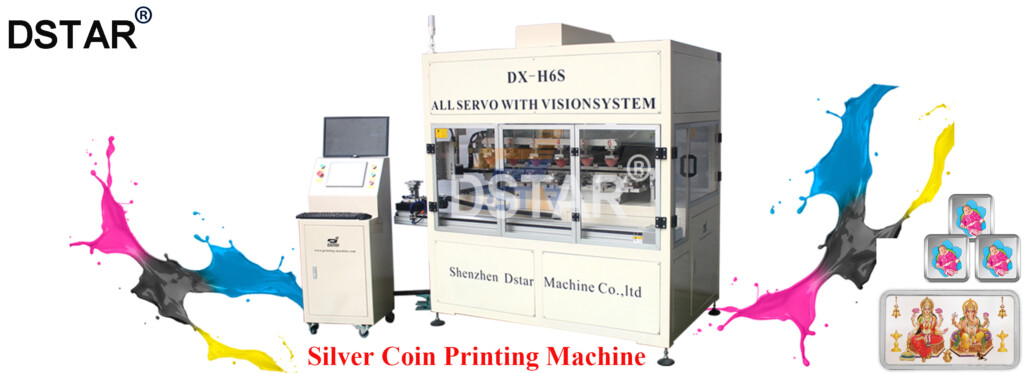

Silver coin printing machine

The automatic silver coin pad printing machine is an advanced piece of equipment specifically designed to apply detailed and high-quality prints on silver coins. This machine leverages the pad printing technique, a versatile and precise method, to ensure that every coin is uniformly decorated with intricate designs, logos, or text.

Key features of silver coin printing machine

Automated Operation: This machine operates with minimal human intervention, which enhances productivity and ensures consistent output. The automation also helps in maintaining a steady workflow and reduces the likelihood of errors.

Precision Printing: The pad printing technique used by this machine is renowned for its accuracy. It can replicate fine details and intricate patterns on the small and often uneven surface of silver coins, ensuring high-quality results.

Versatile Design: The machine is adaptable and can be configured to print on various sizes and shapes of coins. This versatility makes it an excellent choice for mints and other coin-producing facilities.

Efficient Ink Usage: With its efficient ink transfer system, the machine minimizes ink wastage. This not only reduces operational costs but also makes the process more environmentally friendly.

User-Friendly Interface: Equipped with an intuitive control panel, the machine allows operators to easily set parameters and monitor the printing process. This user-friendly interface ensures that even those with minimal technical knowledge can operate the machine effectively.

Durable Construction: Built with high-quality materials, the automatic silver coin pad printing machine is designed to withstand continuous operation in demanding industrial environments. Its robust construction ensures long-term reliability and durability.

Advantages

Enhanced Productivity: By automating the printing process, this machine significantly increases the number of coins that can be printed in a given timeframe, making it ideal for high-volume production.

Consistency and Quality: The precision of pad printing ensures that each coin is printed to the same high standard, maintaining consistency across large batches.

Cost Efficiency: Reduced ink wastage and lower labor costs contribute to overall cost savings. The machine’s efficiency also leads to faster turnaround times, further improving cost-effectiveness.

Customization: The ability to easily change designs and adapt to different coin sizes means that the machine can be used for a wide range of projects, from commemorative coins to regular currency.

Silver coin printing consumables

- Silicone pad

- Pad printing plate

- Coin printing ink

- Coin fixture

- Ink cup

Applications

The automatic silver coin pad printing machine is perfect for mints, coin collectors, and manufacturers who require high-quality printing on coins. It is particularly useful for producing commemorative coins, limited edition series, and other special projects where intricate designs and fine details are essential.

Conclusion

Incorporating an automatic silver coin pad printing machine from DSTAR into your production line can revolutionize the way you print on coins. With its precision, efficiency, and versatility, this DSTAR pad printing machine is an invaluable tool for any facility involved in coin production. It not only enhances the quality of the prints but also significantly boosts productivity, making it a worthy investment for businesses looking to stay ahead in the competitive coin market.

DSTAR machine

DSTAR machine

WeChat

Scan the QR Code with wechat