pet cup printing machine

A plastic pet cup printing machine is a specialized device used for printing designs, logos, or labels on plastic cups made from polyethylene terephthalate (PET). These machines are commonly used in industries such as food and beverage, hospitality, events, and promotional product manufacturing. DSTAR Machine offer a cost-effective and efficient solution for customizing plastic cups with branding or personalized designs.

The printing process of a plastic pet cup printing machine typically involves the following steps:

- Cup Loading(feeding): The machine is designed to hold and position the plastic cups securely during the printing process. Cups are usually loaded onto a rotating fixture or conveyor belt system.

- Surface Preparation: Before printing, the surface of the cups may need to be treated to ensure proper adhesion of the ink or printing material. This can involve techniques such as corona treatment or flame treatment, which enhance the surface energy of the cups for better ink adherence.

- Ink Application: The machine applies ink or printing material onto the cups using various methods such as pad printing, screen printing, or digital printing. The choice of printing method depends on factors like the desired design complexity, production volume, and budget.

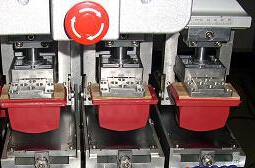

- Pad Printing: This technique involves transferring ink from a specially etched plate (cliché) to a silicone pad, which then presses the ink onto the cup’s surface. It is suitable for simple designs and can achieve precise and consistent results.

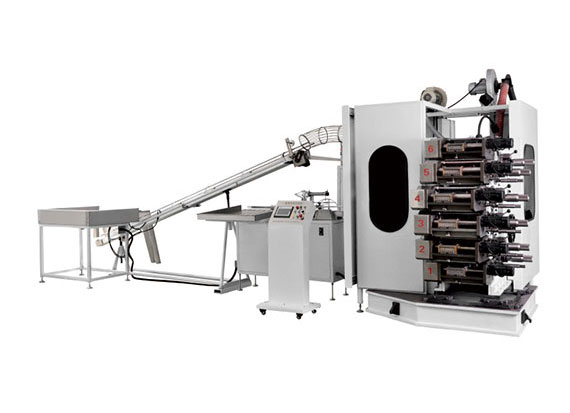

- Screen Printing: In this method, a mesh screen with the desired design is used to transfer ink onto the cups. The ink is forced through the screen using a squeegee, creating the printed pattern on the cup. Screen printing is versatile and can handle more intricate designs.

- Digital Printing: This newer technology involves directly printing the design onto the cups using digital inkjet technology. It offers high-quality, full-color printing and is ideal for small to medium production runs with variable designs.

- Drying or Curing: Once the ink is applied to the cups, it needs to dry or cure to ensure its durability and resistance to abrasion or fading. Some machines may include integrated drying systems, while others require a separate curing process.

- Unloading and Packaging: After the printing and drying process, the cups are unloaded from the machine, inspected for quality control, and prepared for packaging or further processing.

Here are more details about the three common printing methods used in plastic pet cup printing machines:

- Pad Printing:

- Advantages:

- Precise and consistent printing: Pad printing allows for precise placement of the design on the cup’s surface, ensuring accuracy and consistency across multiple cups.

- Ability to print on curved surfaces: The flexibility of the silicone pad enables printing on cups with curved or uneven surfaces.

- Cost-effective for simpler designs: Pad printing is well-suited for simple designs or single-color prints, making it a cost-effective option.

- Fast printing speed: This method can achieve high printing speeds, making it suitable for larger production volumes.

- Limitations:

- Limited color options: Pad printing is primarily used for single-color or limited-color designs. Complex multi-color designs may require additional setup and alignment.

- Longer setup time for new designs: Creating new clichés (plates) for different designs can take time and may require additional costs.

- Not ideal for large coverage areas: Pad printing may not be the best choice for designs that cover a large area of the cup, as it may result in uneven ink distribution.

- Advantages:

- Screen Printing:

- Advantages:

- Versatility in design: Screen printing allows for intricate and detailed designs, making it suitable for cups with complex artwork or multiple colors.

- Vibrant and opaque colors: The thick ink used in screen printing produces vibrant and opaque colors that stand out on the cup’s surface.

- Good ink adhesion: Screen printing provides excellent ink adhesion, resulting in durability and resistance to wear and tear.

- Cost-effective for larger quantities: Screen printing becomes more cost-effective when producing cups in larger quantities.

- Limitations:

- Longer setup time: Screen printing involves the creation of screens for each color, which requires time and additional setup costs.

- Limited flexibility on curved surfaces: While screen printing can accommodate slightly curved surfaces, it may not be suitable for cups with extreme curves or complex shapes.

- Limited gradient or shading capabilities: Achieving smooth gradients or shading effects can be challenging with screen printing, as it typically works best with solid colors and defined shapes.

- Advantages:

- Digital Printing:

- Advantages:

- Full-color and high-resolution printing: Digital printing allows for high-quality, full-color prints with fine details and smooth gradients.

- Variable data printing: Digital printing technology enables customization and the ability to print different designs on each cup, making it ideal for personalized cups or promotional items.

- Quick setup and shorter turnaround time: Digital printing eliminates the need for physical plates or screens, resulting in faster setup and production time.

- No color restrictions: Digital printers can reproduce a wide range of colors, including complex gradients and photographic images.

- Limitations:

- Higher cost for larger quantities: Digital printing can be more expensive per unit for larger production volumes compared to pad or screen printing.

- Limited compatibility with certain cup materials: Digital printing may not be suitable for all types of plastic cups. Compatibility with the cup material should be considered before choosing this method.

- Lower ink durability: While digital printing offers excellent image quality, the ink may have slightly lower durability compared to pad or screen printing, making it more prone to scratching or fading over time.

- Advantages:

When selecting a printing method, it’s important to consider factors such as the complexity of the design, production volume, budget, and desired print quality. Each method has its own strengths and limitations, so choosing the right one depends on your specific requirements and priorities.

It’s important to note that specific features and capabilities of a plastic pet cup printing machine can vary depending on the manufacturer and model. Some machines may offer additional functionalities such as automated feeding, multiple color printing, UV curing, or inline quality control systems.

If you’re interested in purchasing or learning more about plastic pet cup printing machines, I recommend contacting DSTAR Machine who is specialize in this field. We can provide detailed information on available models, pricing, and technical specifications to help you choose the right machine for your specific requirements.

DSTAR machine

DSTAR machine

WeChat

Scan the QR Code with wechat